Page 362 - Boiler_Operators_Handbook,_Second_Edition

P. 362

Plants and Equipment 347

Figure 10-86. Centrifugal fan shape

as opposed to blower

can break and the rest can still carry normal loads. The

problem is that the one belt that breaks usually gets

tangled with the others with complete failure. I don’t

like belt driven fans and blowers and believe that there

are a sufficient number of choices of fans at standard

motor speeds to use direct drive fans on boilers. With

the growth of variable speed drives where we can run a

fan at any speed we choose we don’t need belts. I’m defi-

nitely opposed to belts because they’re a maintenance

item and produce unnecessary radial loads on fan shafts

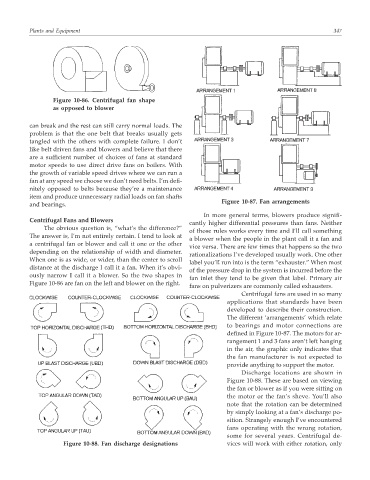

Figure 10-87. Fan arrangements

and bearings.

In more general terms, blowers produce signifi-

Centrifugal Fans and Blowers

cantly higher differential pressures than fans. Neither

The obvious question is, “what’s the difference?”

of those rules works every time and I’ll call something

The answer is, I’m not entirely certain. I tend to look at

a blower when the people in the plant call it a fan and

a centrifugal fan or blower and call it one or the other

vice versa. There are few times that happens so the two

depending on the relationship of width and diameter.

rationalizations I’ve developed usually work. One other

When one is as wide, or wider, than the center to scroll

label you’ll run into is the term “exhauster.” When most

distance at the discharge I call it a fan. When it’s obvi-

of the pressure drop in the system is incurred before the

ously narrow I call it a blower. So the two shapes in

fan inlet they tend to be given that label. Primary air

Figure 10-86 are fan on the left and blower on the right.

fans on pulverizers are commonly called exhausters.

Centrifugal fans are used in so many

applications that standards have been

developed to describe their construction.

The different ‘arrangements’ which relate

to bearings and motor connections are

defined in Figure 10-87. The motors for ar-

rangement 1 and 3 fans aren’t left hanging

in the air, the graphic only indicates that

the fan manufacturer is not expected to

provide anything to support the motor.

Discharge locations are shown in

Figure 10-88. These are based on viewing

the fan or blower as if you were sitting on

the motor or the fan’s sheve. You’ll also

note that the rotation can be determined

by simply looking at a fan’s discharge po-

sition. Strangely enough I’ve encountered

fans operating with the wrong rotation,

some for several years. Centrifugal de-

Figure 10-88. Fan discharge designations vices will work with either rotation, only