Page 110 - Boiler plant and distribution system optimization manual

P. 110

Boiler Tuneup 95

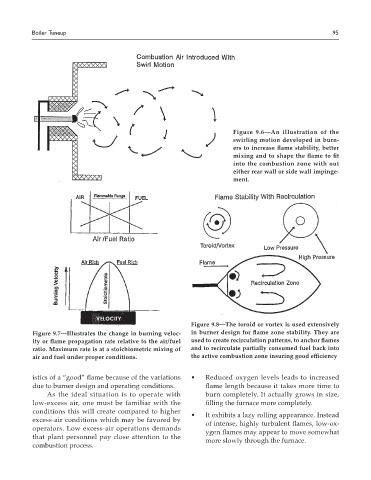

Figure 9.6—An illustration of the

swirling motion developed in burn-

ers to increase flame stability, better

mixing and to shape the flame to fit

into the combustion zone with out

either rear wall or side wall impinge-

ment.

velocity

Figure 9.8—The toroid or vortex is used extensively

Figure 9.7—Illustrates the change in burning veloc- in burner design for flame zone stability. They are

ity or flame propagation rate relative to the air/fuel used to create recirculation patterns, to anchor flames

ratio. Maximum rate is at a stoichiometric mixing of and to recirculate partially consumed fuel back into

air and fuel under proper conditions. the active combustion zone insuring good efficiency

istics of a “good” flame because of the variations • Reduced oxygen levels leads to increased

due to burner design and operating conditions. flame length because it takes more time to

As the ideal situation is to operate with burn completely. It actually grows in size,

low-excess air, one must be familiar with the filling the furnace more completely.

conditions this will create compared to higher

• It exhibits a lazy rolling appearance. Instead

excess-air conditions which may be favored by

of intense, highly turbulent flames, low-ox-

operators. Low excess-air operations demands

ygen flames may appear to move somewhat

that plant personnel pay close attention to the

more slowly through the furnace.

combustion process.