Page 166 - Boiler plant and distribution system optimization manual

P. 166

Over 100 Ways to Improve Efficiency 151

Figure 10.43—Steam separators keeps steam piping system clean and dry.

heat pumps to raise the water temperature for lo-

cal heating and process demands.

The key to how this operates is in the term:

Coefficient of Performance (COP), a measure of

the ratio of energy output to energy input. Some

heat pump units have a COP of over 5 which

means the energy to operate them is only about

20% of the energy produced. (Figure 10.46)

Advantages/Disadvantages

This is one of those options that take imag-

ination and initiative. There appears to be many

applications where the efficiency of the Heat Figure 10.44—Heat Pumps can introduce high effi-

ciencies when combined with other technologies.

Pump has not been applied; for example for heat-

ing make up water or to augment old low pres-

sure steam systems. First cost, operation and

maintenance expenses are involved which must

be worked out. It is a good way to recover low

grade waste heat or provide heat to isolated lo-

cations without resorting to extensive piping sys-

tems and the heat losses they represent.

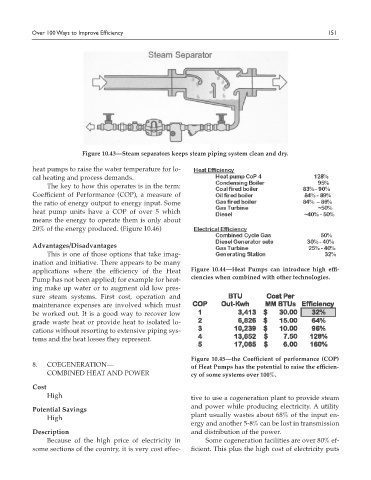

Figure 10.45—the Coefficient of performance (COP)

8. COEGENERATION—

of Heat Pumps has the potential to raise the efficien-

COMBINED HEAT AND POWER cy of some systems over 100%.

Cost

High tive to use a cogeneration plant to provide steam

and power while producing electricity. A utility

Potential Savings

plant usually wastes about 68% of the input en-

High

ergy and another 5-8% can be lost in transmission

Description and distribution of the power.

Because of the high price of electricity in Some cogeneration facilities are over 80% ef-

some sections of the country, it is very cost effec- ficient. This plus the high cost of electricity puts