Page 93 - Boiler plant and distribution system optimization manual

P. 93

78 Boiler Plant and Distribution System Optimization Manual

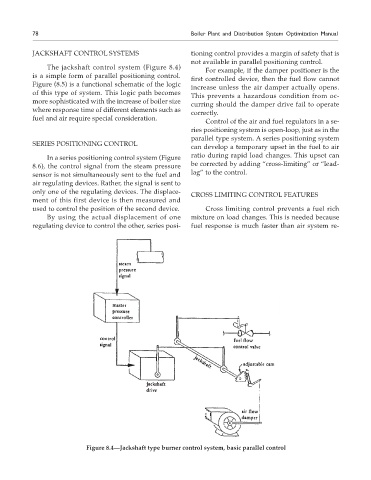

JACKSHAFT CONTROL SYSTEMS tioning control provides a margin of safety that is

not available in parallel positioning control.

The jackshaft control system (Figure 8.4)

For example, if the damper positioner is the

is a simple form of parallel positioning control.

first controlled device, then the fuel flow cannot

Figure (8.5) is a functional schematic of the logic

increase unless the air damper actually opens.

of this type of system. This logic path becomes

This prevents a hazardous condition from oc-

more sophisticated with the increase of boiler size

curring should the damper drive fail to operate

where response time of different elements such as

correctly.

fuel and air require special consideration.

Control of the air and fuel regulators in a se-

ries positioning system is open-loop, just as in the

parallel type system. A series positioning system

SERIES POSITIONING CONTROL

can develop a temporary upset in the fuel to air

In a series positioning control system (Figure ratio during rapid load changes. This upset can

8.6), the control signal from the steam pressure be corrected by adding “cross-limiting” or “lead-

sensor is not simultaneously sent to the fuel and lag” to the control.

air regulating devices. Rather, the signal is sent to

only one of the regulating devices. The displace-

CROSS LIMITING CONTROL FEATURES

ment of this first device is then measured and

used to control the position of the second device. Cross limiting control prevents a fuel rich

By using the actual displacement of one mixture on load changes. This is needed because

regulating device to control the other, series posi- fuel response is much faster than air system re-

Figure 8.4—Jackshaft type burner control system, basic parallel control