Page 94 - Boiler plant and distribution system optimization manual

P. 94

The Control of Boilers 79

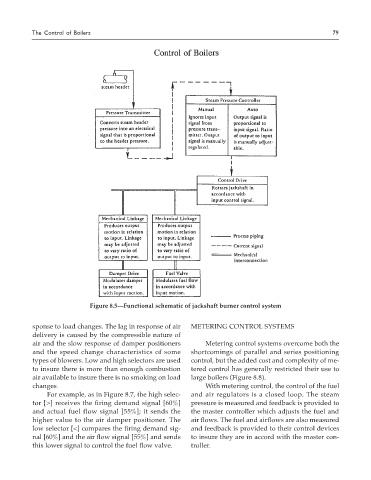

Figure 8.5—Functional schematic of jackshaft burner control system

sponse to load changes. The lag in response of air METERING CONTROL SYSTEMS

delivery is caused by the compressible nature of

air and the slow response of damper positioners Metering control systems overcome both the

and the speed change characteristics of some shortcomings of parallel and series positioning

types of blowers. Low and high selectors are used control, but the added cost and complexity of me-

to insure there is more than enough combustion tered control has generally restricted their use to

air available to insure there is no smoking on load large boilers (Figure 8.8).

changes. With metering control, the control of the fuel

For example, as in Figure 8.7, the high selec- and air regulators is a closed loop. The steam

tor [>] receives the firing demand signal [60%] pressure is measured and feedback is provided to

and actual fuel flow signal [55%]; it sends the the master controller which adjusts the fuel and

higher value to the air damper positioner. The air flows. The fuel and airflows are also measured

low selector [<] compares the firing demand sig- and feedback is provided to their control devices

nal [60%] and the air flow signal [55%] and sends to insure they are in accord with the master con-

this lower signal to control the fuel flow valve. troller.