Page 95 - Boiler plant and distribution system optimization manual

P. 95

80 Boiler Plant and Distribution System Optimization Manual

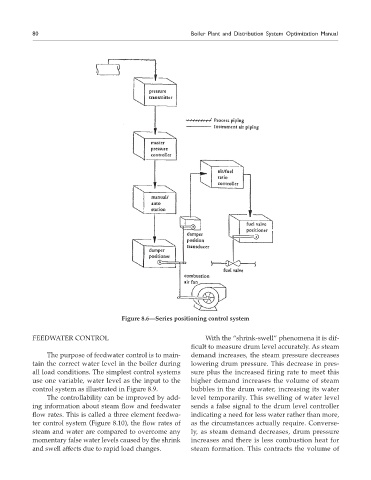

Figure 8.6—Series positioning control system

FEEDWATER CONTROL With the “shrink-swell” phenomena it is dif-

ficult to measure drum level accurately. As steam

The purpose of feedwater control is to main- demand increases, the steam pressure decreases

tain the correct water level in the boiler during lowering drum pressure. This decrease in pres-

all load conditions. The simplest control systems sure plus the increased firing rate to meet this

use one variable, water level as the input to the higher demand increases the volume of steam

control system as illustrated in Figure 8.9. bubbles in the drum water, increasing its water

The controllability can be improved by add- level temporarily. This swelling of water level

ing information about steam flow and feedwater sends a false signal to the drum level controller

flow rates. This is called a three element feedwa- indicating a need for less water rather than more,

ter control system (Figure 8.10), the flow rates of as the circumstances actually require. Converse-

steam and water are compared to overcome any ly, as steam demand decreases, drum pressure

momentary false water levels caused by the shrink increases and there is less combustion heat for

and swell affects due to rapid load changes. steam formation. This contracts the volume of