Page 84 - Budgeting for Managers

P. 84

CPU

Monitor

Keyboard

Materials needed per unit

1

1

1

Total production needs (units

times production needs) Creating a Production Budget 55,000 67

55,000

55,000

Less in-progress inventory 0 0 0

Add: desired ending inventory 10,000 10,000 10,000

Total direct materials needed 65,000 65,000 65,000

Less: beginning inventory materials 2,000 3,000 1,500

Direct materials to be purchased 63,000 62,000 63,500

Cost per unit $300 $100 $25

Cost of materials (per item) $18,900,000 $6,200,000 $1,587,500

Sum of materials to be purchased

(all items) $26,687,500

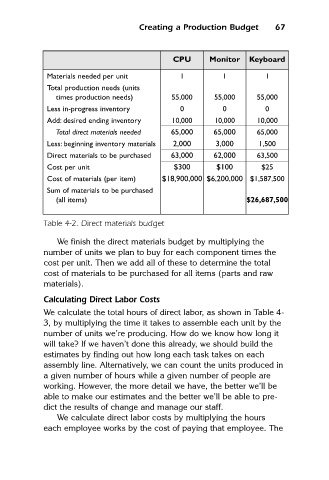

Table 4-2. Direct materials budget

We finish the direct materials budget by multiplying the

number of units we plan to buy for each component times the

cost per unit. Then we add all of these to determine the total

cost of materials to be purchased for all items (parts and raw

materials).

Calculating Direct Labor Costs

We calculate the total hours of direct labor, as shown in Table 4-

3, by multiplying the time it takes to assemble each unit by the

number of units we’re producing. How do we know how long it

will take? If we haven’t done this already, we should build the

estimates by finding out how long each task takes on each

assembly line. Alternatively, we can count the units produced in

a given number of hours while a given number of people are

working. However, the more detail we have, the better we’ll be

able to make our estimates and the better we’ll be able to pre-

dict the results of change and manage our staff.

We calculate direct labor costs by multiplying the hours

each employee works by the cost of paying that employee. The