Page 136 - Building A Succesful Board-Test Strategy

P. 136

122 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

a board simulation—and metrology tools to establish pass/fail criteria. Some

systems learn from a known-good board (subject to the usual caveats), and can

automatically locate, inspect, and evaluate each solder connection. This approach

involves training the system to recognize all of the solder-joint geometries that it

must inspect and storing the information in a library with corresponding thresh-

olds and tolerances. The engineer can modify the library criteria to allow for

deviations and customizations.

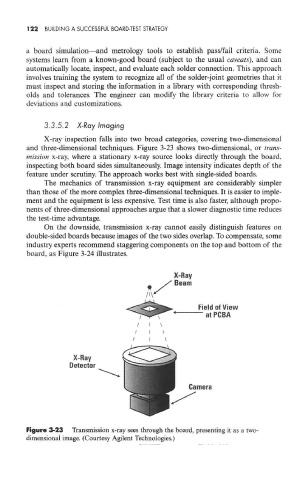

3.3.5.2 X-Ray Imaging

X-ray inspection falls into two broad categories, covering two-dimensional

and three-dimensional techniques. Figure 3-23 shows two-dimensional, or trans-

mission x-ray, where a stationary x-ray source looks directly through the board,

inspecting both board sides simultaneously. Image intensity indicates depth of the

feature under scrutiny. The approach works best with single-sided boards.

The mechanics of transmission x-ray equipment are considerably simpler

than those of the more complex three-dimensional techniques. It is easier to imple-

ment and the equipment is less expensive. Test time is also faster, although propo-

nents of three-dimensional approaches argue that a slower diagnostic time reduces

the test-time advantage.

On the downside, transmission x-ray cannot easily distinguish features on

double-sided boards because images of the two sides overlap. To compensate, some

industry experts recommend staggering components on the top and bottom of the

board, as Figure 3-24 illustrates.

Figure 3-23 Transmission x-ray sees through the board, presenting it as a two-

dimensional image. (Courtesy Agilent Technologies.)