Page 140 - Building A Succesful Board-Test Strategy

P. 140

126 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

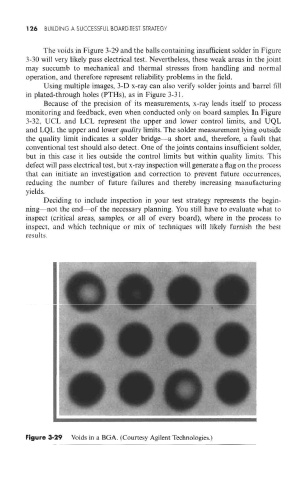

The voids in Figure 3-29 and the balls containing insufficient solder in Figure

3-30 will very likely pass electrical test. Nevertheless, these weak areas in the joint

may succumb to mechanical and thermal stresses from handling and normal

operation, and therefore represent reliability problems in the field.

Using multiple images, 3-D x-ray can also verify solder joints and barrel fill

in plated-through holes (PTHs), as in Figure 3-31.

Because of the precision of its measurements, x-ray lends itself to process

monitoring and feedback, even when conducted only on board samples. In Figure

3-32, UCL and LCL represent the upper and lower control limits, and UQL

and LQL the upper and lower quality limits. The solder measurement lying outside

the quality limit indicates a solder bridge—a short and, therefore, a fault that

conventional test should also detect. One of the joints contains insufficient solder,

but in this case it lies outside the control limits but within quality limits. This

detect will pass electrical test, but x-ray inspection will generate a flag on the process

that can initiate an investigation and correction to prevent future occurrences,

reducing the number of future failures and thereby increasing manufacturing

yields.

Deciding to include inspection in your test strategy represents the begin-

ning— not the end—of the necessary planning. You still have to evaluate what to

inspect (critical areas, samples, or all of every board), where in the process to

inspect, and which technique or mix of techniques will likely furnish the best

results.

Figure 3-29 Voids in a EGA. (Courtesy Agilent Technologies.)