Page 138 - Building A Succesful Board-Test Strategy

P. 138

124 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

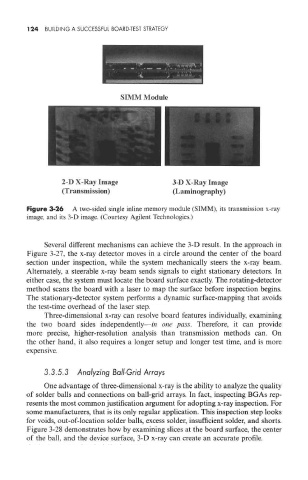

Figure 3-26 A two-sided single inline memory module (SIMM), its transmission x-ray

image, and its 3-D image. (Courtesy Agilent Technologies.)

Several different mechanisms can achieve the 3-D result. In the approach in

Figure 3-27, the x-ray detector moves in a circle around the center of the board

section under inspection, while the system mechanically steers the x-ray beam.

Alternately, a steerable x-ray beam sends signals to eight stationary detectors. In

either case, the system must locate the board surface exactly. The rotating-detector

method scans the board with a laser to map the surface before inspection begins.

The stationary-detector system performs a dynamic surface-mapping that avoids

the test-time overhead of the laser step.

Three-dimensional x-ray can resolve board features individually, examining

the two board sides independently—in one pass. Therefore, it can provide

more precise, higher-resolution analysis than transmission methods can. On

the other hand, it also requires a longer setup and longer test time, and is more

expensive,

3.3.5.3 Analyzing Ball-Grid Arrays

One advantage of three-dimensional x-ray is the ability to analyze the quality

of solder balls and connections on ball-grid arrays. In fact, inspecting BGAs rep-

resents the most common justification argument for adopting x-ray inspection. For

some manufacturers, that is its only regular application. This inspection step looks

for voids, out-of-location solder balls, excess solder, insufficient solder, and shorts.

Figure 3-28 demonstrates how by examining slices at the board surface, the center

of the ball, and the device surface, 3-D x-ray can create an accurate profile.