Page 58 - Building A Succesful Board-Test Strategy

P. 58

44 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

_ Conception Validation Development Production Operation Support

Time

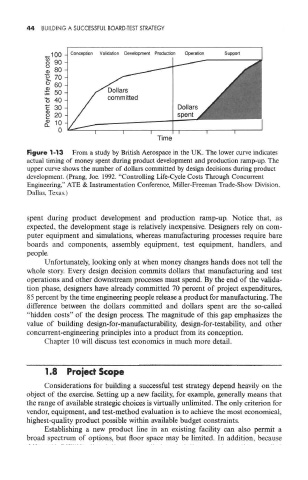

Figure 1-13 From a study by British Aerospace in the UK. The lower curve indicates

actual timing of money spent during product development and production ramp-up. The

upper curve shows the number of dollars committed by design decisions during product

development. (Prang, Joe. 1992. "Controlling Life-Cycle Costs Through Concurrent

Engineering," ATE & Instrumentation Conference, Miller-Freeman Trade-Show Division,

Dallas, Texas.)

spent during product development and production ramp-up. Notice that, as

expected, the development stage is relatively inexpensive. Designers rely on com-

puter equipment and simulations, whereas manufacturing processes require bare

boards and components, assembly equipment, test equipment, handlers, and

people.

Unfortunately, looking only at when money changes hands does not tell the

whole story. Every design decision commits dollars that manufacturing and test

operations and other downstream processes must spend. By the end of the valida-

tion phase, designers have already committed 70 percent of project expenditures,

85 percent by the time engineering people release a product for manufacturing. The

difference between the dollars committed and dollars spent are the so-called

"hidden costs" of the design process. The magnitude of this gap emphasizes the

value of building design-for-manufacturability, design-for-testability, and other

concurrent-engineering principles into a product from its conception.

Chapter 10 will discuss test economics in much more detail.

1.8 Project Scope

Considerations for building a successful test strategy depend heavily on the

object of the exercise. Setting up a new facility, for example, generally means that

the range of available strategic choices is virtually unlimited. The only criterion for

vendor, equipment, and test-method evaluation is to achieve the most economical,

highest-quality product possible within available budget constraints.

Establishing a new product line in an existing facility can also permit a

broad spectrum of options, but floor space may be limited. In addition, because