Page 293 - CNC Robotics

P. 293

Chapter 12 1 Examples

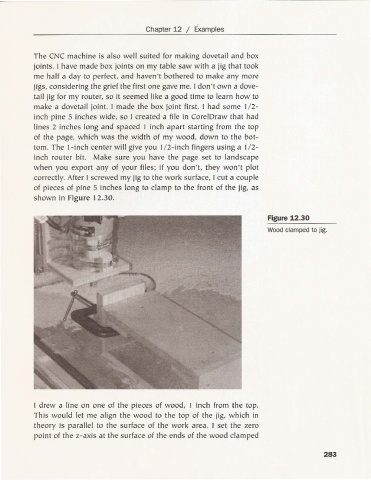

The CNC mach ine is also well suited for making dovetail and box

joints. I have made box joi nts on my table saw with a jig that took

me half a day to perfect, and haven't bothered to make any more

jigs, consideri ng the grief the first one gave me. I don 't own a dove-

tail jig for my router, so it seemed like a good time to learn how to

make a dovetai l joint. I made the box joint fi rst. I had som e 1/2-

inch pine 5 inches w ide, so I created a file in CorelDraw that had

lin es 2 in ches long and spaced I inch apart starting from the top

of the page, w hich was the w idt h of my wood, down to the bot-

tom . The I -inch center will give you 1/ 2-inch fingers using a 1/ 2-

inch rou ter bit. Make sure you have the page set to landscape

w hen you export any of your files; if you don 't , they won't plot

correctly. After I screwed my jig to the work surface, I cut a couple

of pieces of pin e 5 inches long to cla mp to the front of the jig, as

shown in Figu re 12 .30.

Figure 12.30

Wood clamped to jig.

I drew a line on one of the pieces of wood, I inch from the top .

This would let me align the wood to the top of the jig , w hich in

theory is parallel to the surface of the work area. I set th e zero

point of the z-axls at the surface of the end s of the wood clamped

283