Page 294 - CNC Robotics

P. 294

CNC Robotics

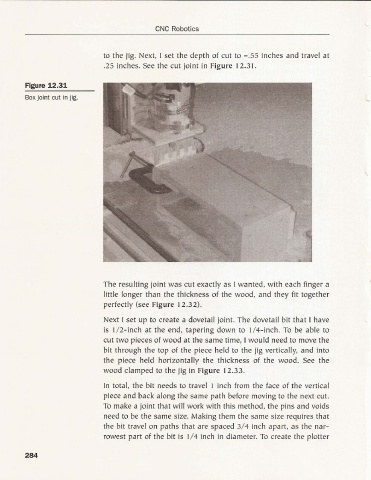

to the jig. Next, 1set the depth of cut to - .55 inches and travel at

.25 inch es. See the cut joint in Figure 12.31.

Figure 12.31

Box joint cut in jig.

The resultin g joint was cut exactly as I wanted, wit h each finger a

little longe r tha n the thickness of the wood, and they fit together

perfectly (see Figure 12.32).

Next I set up to create a dovetail joint. The dovetail bit that I have

is 1/2-in ch at the end, tapering down to 1/4-i nch . To be able to

cut two pieces of wood at the sa me time, I wo uld need to move the

bit th rough the top of the piece he ld to the jig vertically, a nd into

the piece held horizontally the thickness of the wood. See the

wood clamped to the jig in Figure 12.33.

In total, the bit needs to travel I inch from the face of the vertical

piece a nd back along the sa me path befo re moving to the next cut.

To ma ke a joint that will wo rk with this method, the pins and voids

need to be the sa me size. Making them the same size requires that

the bit travel on paths tha t are spaced 3/4 inch apart, as the na r-

rowest part of the bit is 1/ 4 inch in diameter. To create the plotter

284