Page 297 - CNC Robotics

P. 297

Chapter 12 / Examples

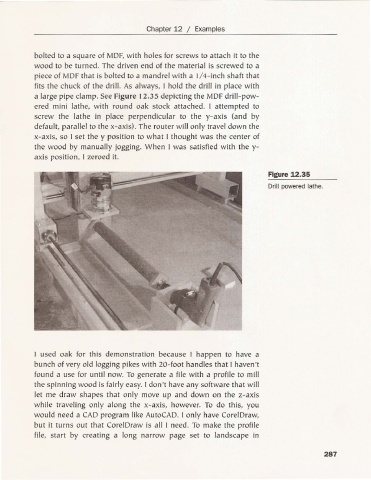

bolted to a sq uare of MDF, with holes for screws to attach it to th e

wood to be tu rned . The dr iven end of the material is screwed to a

piec e of MDF tha t is bolted to a ma ndrel wit h a 1/4-inch shaft that

fits the ch uck of the drill. As always, I hold the drill in place with

a large pipe clamp. See Figure 12.35 de picting the MDF drill-pow-

ered mini lathe, with round oak stock attached. I attempted to

sc rew the lathe in place perpendicular to the y-ax is (and by

default, para llel to the x-axis). The router will only travel down the

x-axis, so I se t the y position to what I thought was the cen ter of

the wood by manually jogging. Wh en I was satisfied with the y-

ax is position , I ze roed it.

Figure 12.35

Drill powered lathe.

I used oak for this demonstration because I happen to ha ve a

bunch of very old logging pikes with 20-foot handles that I haven't

fou nd a use for until now. To generate a file with a profile to mill

the spinning wood is fairly easy. I don't have any software that will

let me draw shapes that only move up a nd down on the z-ax is

while trave ling only along the x-ax is, however. To do thi s, you

would need a CAD program like AutoCAD. I on ly have CorelDraw,

but it turn s out th at CorelDraw is all I need. To make the profile

file, sta rt by creating a long narrow page set to lands cape in

287