Page 296 - CNC Robotics

P. 296

CNC Robotics

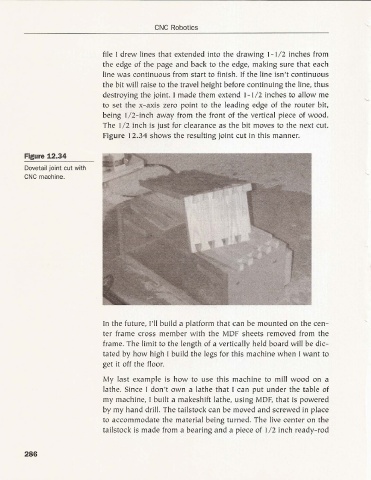

file I drew lines that exte nded into the drawing 1-1 / 2 inches from

the edge of the page a nd back to the edge, making sure that each

line was co ntin uo us from start to finis h. If the line isn 't co ntinuo us

the bit will raise to the travel heigh t before co ntinui ng the line, th us

destroying the joint. I made them extend 1- 1/ 2 inches to a llow me

to set the x-axis zero point to the leading edge of the route r bit,

being i / z- tnch away from the front of the vertica l piece of wood.

The 1/2 inch is just for clea ran ce as the bit moves to the next cut.

Figure 12.34 shows the resulting joint cut in this ma nner.

Figure 12.34

Dovetail joint cut with

eNC machine.

In the futu re, I'll build a platform that can be mo unted on the cen-

ter fra me cross member with the MDF sheets removed from the

frame. The limit to the length of a vertically held board will be dic-

tated by how high t build the legs for this machine when I want to

ge t it off the floor.

My last exa mp le is how to use this machine to mill wood on a

lathe. Since I do n't own a lath e that I can put under the table of

my ma chine, I built a ma keshi ft lat he, using MDF, that is powered

by my hand drill. The ta ilstoc k ca n be moved a nd screwed in place

to accommodate the material be ing turned. The live center on the

ta ilstock is made from a bearing and a piece of 1/2 inch ready-rod

286