Page 235 - Cam Design Handbook

P. 235

THB8 9/19/03 7:25 PM Page 223

CAM MECHANISM FORCES 223

Displacement

+

–

Follower

inertia

Spring

force force

Load margin

(critical point)

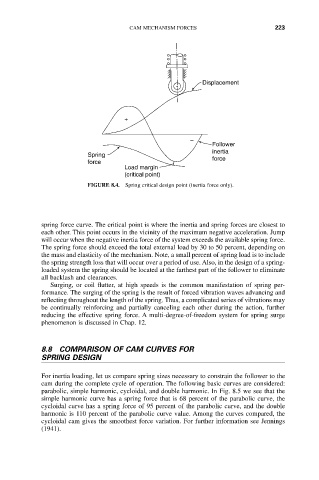

FIGURE 8.4. Spring critical design point (inertia force only).

spring force curve. The critical point is where the inertia and spring forces are closest to

each other. This point occurs in the vicinity of the maximum negative acceleration. Jump

will occur when the negative inertia force of the system exceeds the available spring force.

The spring force should exceed the total external load by 30 to 50 percent, depending on

the mass and elasticity of the mechanism. Note, a small percent of spring load is to include

the spring strength loss that will occur over a period of use. Also, in the design of a spring-

loaded system the spring should be located at the farthest part of the follower to eliminate

all backlash and clearances.

Surging, or coil flutter, at high speeds is the common manifestation of spring per-

formance. The surging of the spring is the result of forced vibration waves advancing and

reflecting throughout the length of the spring. Thus, a complicated series of vibrations may

be continually reinforcing and partially canceling each other during the action, further

reducing the effective spring force. A multi-degree-of-freedom system for spring surge

phenomenon is discussed in Chap. 12.

8.8 COMPARISON OF CAM CURVES FOR

SPRING DESIGN

For inertia loading, let us compare spring sizes necessary to constrain the follower to the

cam during the complete cycle of operation. The following basic curves are considered:

parabolic, simple harmonic, cycloidal, and double harmonic. In Fig. 8.5 we see that the

simple harmonic curve has a spring force that is 68 percent of the parabolic curve, the

cycloidal curve has a spring force of 95 percent of the parabolic curve, and the double

harmonic is 110 percent of the parabolic curve value. Among the curves compared, the

cycloidal cam gives the smoothest force variation. For further information see Jennings

(1941).