Page 237 - Cam Design Handbook

P. 237

THB8 9/19/03 7:25 PM Page 225

CAM MECHANISM FORCES 225

Motor Clutch-brake

unit

Worm gear

Cam

Follower Load

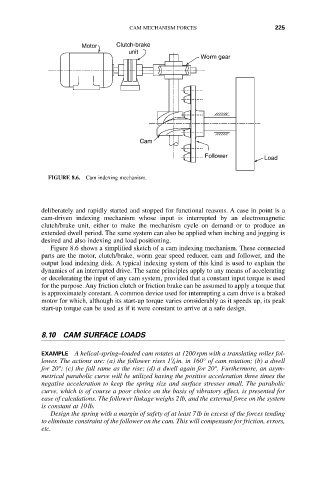

FIGURE 8.6. Cam indexing mechanism.

deliberately and rapidly started and stopped for functional reasons. A case in point is a

cam-driven indexing mechanism whose input is interrupted by an electromagnetic

clutch/brake unit, either to make the mechanism cycle on demand or to produce an

extended dwell period. The same system can also be applied when inching and jogging is

desired and also indexing and load positioning.

Figure 8.6 shows a simplified sketch of a cam indexing mechanism. These connected

parts are the motor, clutch/brake, worm gear speed reducer, cam and follower, and the

output load indexing disk. A typical indexing system of this kind is used to explain the

dynamics of an interrupted drive. The same principles apply to any means of accelerating

or decelerating the input of any cam system, provided that a constant input torque is used

for the purpose. Any friction clutch or friction brake can be assumed to apply a torque that

is approximately constant. A common device used for interrupting a cam drive is a braked

motor for which, although its start-up torque varies considerably as it speeds up, its peak

start-up torque can be used as if it were constant to arrive at a safe design.

8.10 CAM SURFACE LOADS

EXAMPLE A helical-spring–loaded cam rotates at 1200rpm with a translating roller fol-

1

lower. The actions are: (a) the follower rises 1 / 4 in. in 160° of cam rotation; (b) a dwell

for 20°; (c) the fall same as the rise; (d) a dwell again for 20°. Furthermore, an asym-

metrical parabolic curve will be utilized having the positive acceleration three times the

negative acceleration to keep the spring size and surface stresses small. The parabolic

curve, which is of course a poor choice on the basis of vibratory effect, is presented for

ease of calculations. The follower linkage weighs 2lb, and the external force on the system

is constant at 10lb.

Design the spring with a margin of safety of at least 7lb in excess of the forces tending

to eliminate constraint of the follower on the cam. This will compensate for friction, errors,

etc.