Page 537 - Cam Design Handbook

P. 537

THB15 9/19/03 8:03 PM Page 525

CAMS IN MICROELECTROMECHANICAL SYSTEMS 525

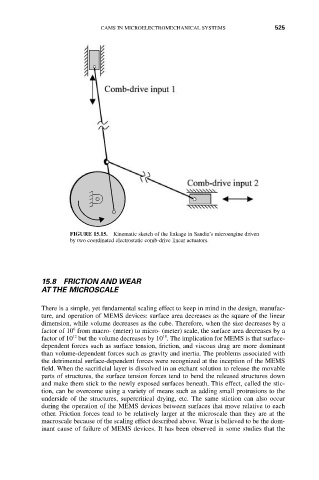

FIGURE 15.15. Kinematic sketch of the linkage in Sandia’s microengine driven

by two coordinated electrostatic comb-drive linear actuators.

15.8 FRICTION AND WEAR

AT THE MICROSCALE

There is a simple, yet fundamental scaling effect to keep in mind in the design, manufac-

ture, and operation of MEMS devices: surface area decreases as the square of the linear

dimension, while volume decreases as the cube. Therefore, when the size decreases by a

6

factor of 10 from macro- (meter) to micro- (meter) scale, the surface area decreases by a

18

12

factor of 10 but the volume decreases by 10 . The implication for MEMS is that surface-

dependent forces such as surface tension, friction, and viscous drag are more dominant

than volume-dependent forces such as gravity and inertia. The problems associated with

the detrimental surface-dependent forces were recognized at the inception of the MEMS

field. When the sacrificial layer is dissolved in an etchant solution to release the movable

parts of structures, the surface tension forces tend to bend the released structures down

and make them stick to the newly exposed surfaces beneath. This effect, called the stic-

tion, can be overcome using a variety of means such as adding small protrusions to the

underside of the structures, supercritical drying, etc. The same stiction can also occur

during the operation of the MEMS devices between surfaces that move relative to each

other. Friction forces tend to be relatively larger at the microscale than they are at the

macroscale because of the scaling effect described above. Wear is believed to be the dom-

inant cause of failure of MEMS devices. It has been observed in some studies that the