Page 534 - Cam Design Handbook

P. 534

THB15 9/19/03 8:03 PM Page 522

522 CAM DESIGN HANDBOOK

and rotary actuators are described here. It is interesting to note that it is often not practi-

cal to take power out of rotary motors to transmit to other components. The problem lies

in attaching the other components. Recently this problem has been overcome by some

indirect means. Such a design, called a microengine, is also described in this section.

15.7.1 Electrostatic Micromotors

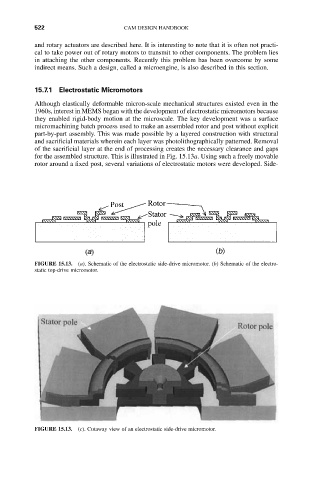

Although elastically deformable micron-scale mechanical structures existed even in the

1960s, interest in MEMS began with the development of electrostatic micromotors because

they enabled rigid-body motion at the microscale. The key development was a surface

micromachining batch process used to make an assembled rotor and post without explicit

part-by-part assembly. This was made possible by a layered construction with structural

and sacrificial materials wherein each layer was photolithographically patterned. Removal

of the sacrificial layer at the end of processing creates the necessary clearance and gaps

for the assembled structure. This is illustrated in Fig. 15.13a. Using such a freely movable

rotor around a fixed post, several variations of electrostatic motors were developed. Side-

FIGURE 15.13. (a). Schematic of the electrostatic side-drive micromotor. (b) Schematic of the electro-

static top-drive micromotor.

FIGURE 15.13. (c). Cutaway view of an electrostatic side-drive micromotor.