Page 530 - Cam Design Handbook

P. 530

THB15 9/19/03 8:03 PM Page 518

518 CAM DESIGN HANDBOOK

another component. If a wrong decision is made during the sequence, the pin gets stuck

in the wheel. This device is equipped with an antireverse spring so that an incorrect

sequence cannot be corrected by trial and error. Amodified design with a translating groove

cam is discussed next.

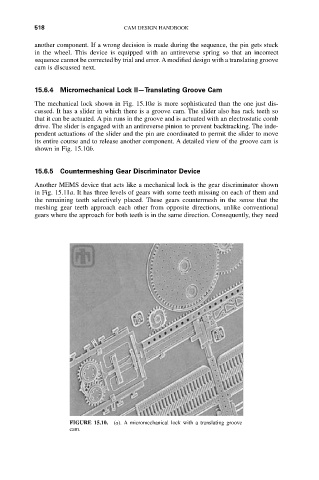

15.6.4 Micromechanical Lock II—Translating Groove Cam

The mechanical lock shown in Fig. 15.10a is more sophisticated than the one just dis-

cussed. It has a slider in which there is a groove cam. The slider also has rack teeth so

that it can be actuated. A pin runs in the groove and is actuated with an electrostatic comb

drive. The slider is engaged with an antireverse pinion to prevent backtracking. The inde-

pendent actuations of the slider and the pin are coordinated to permit the slider to move

its entire course and to release another component. A detailed view of the groove cam is

shown in Fig. 15.10b.

15.6.5 Countermeshing Gear Discriminator Device

Another MEMS device that acts like a mechanical lock is the gear discriminator shown

in Fig. 15.11a. It has three levels of gears with some teeth missing on each of them and

the remaining teeth selectively placed. These gears countermesh in the sense that the

meshing gear teeth approach each other from opposite directions, unlike conventional

gears where the approach for both teeth is in the same direction. Consequently, they need

FIGURE 15.10. (a). A micromechanical lock with a translating groove

cam.