Page 527 - Cam Design Handbook

P. 527

THB15 9/19/03 8:03 PM Page 515

CAMS IN MICROELECTROMECHANICAL SYSTEMS 515

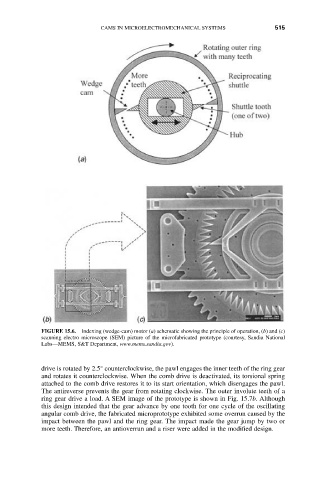

FIGURE 15.6. Indexing (wedge-cam) motor (a) schematic showing the principle of operation, (b) and (c)

scanning electro microscope (SEM) picture of the microfabricated prototype (courtesy, Sandia National

Labs—MEMS, S&T Department, www.mems.sandia.gov).

drive is rotated by 2.5° counterclockwise, the pawl engages the inner teeth of the ring gear

and rotates it counterclockwise. When the comb drive is deactivated, its torsional spring

attached to the comb drive restores it to its start orientation, which disengages the pawl.

The antireverse prevents the gear from rotating clockwise. The outer involute teeth of a

ring gear drive a load. A SEM image of the prototype is shown in Fig. 15.7b. Although

this design intended that the gear advance by one tooth for one cycle of the oscillating

angular comb drive, the fabricated microprototype exhibited some overrun caused by the

impact between the pawl and the ring gear. The impact made the gear jump by two or

more teeth. Therefore, an antioverrun and a riser were added in the modified design.