Page 524 - Cam Design Handbook

P. 524

THB15 9/19/03 8:03 PM Page 512

512 CAM DESIGN HANDBOOK

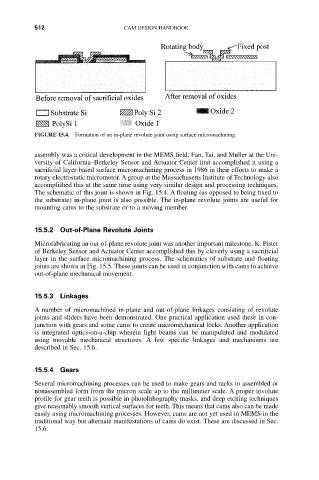

FIGURE 15.4. Formation of an in-plane revolute joint using surface micromachining.

assembly was a critical development in the MEMS field. Fan, Tai, and Muller at the Uni-

versity of California–Berkeley Sensor and Actuator Center first accomplished it using a

sacrificial layer-based surface micromachining process in 1986 in their efforts to make a

rotary electrostatic micromotor. A group at the Massachusetts Institute of Technology also

accomplished this at the same time using very similar design and processing techniques.

The schematic of this joint is shown in Fig. 15.4. A floating (as opposed to being fixed to

the substrate) in-plane joint is also possible. The in-plane revolute joints are useful for

mounting cams to the substrate or to a moving member.

15.5.2 Out-of-Plane Revolute Joints

Microfabricating an out-of-plane revolute joint was another important milestone. K. Pister

of Berkeley Sensor and Actuator Center accomplished this by cleverly using a sacrificial

layer in the surface micromachining process. The schematics of substrate and floating

joints are shown in Fig. 15.5. These joints can be used in conjunction with cams to achieve

out-of-plane mechanical movement.

15.5.3 Linkages

A number of micromachined in-plane and out-of-plane linkages consisting of revolute

joints and sliders have been demonstrated. One practical application used these in con-

junction with gears and some cams to create micromechanical locks. Another application

is integrated optics-on-a-chip wherein light beams can be manipulated and modulated

using movable mechanical structures. A few specific linkages and mechanisms are

described in Sec. 15.6.

15.5.4 Gears

Several micromachining processes can be used to make gears and racks in assembled or

nonassembled form from the micron scale up to the millimeter scale. A proper involute

profile for gear teeth is possible in photolithography masks, and deep etching techniques

give reasonably smooth vertical surfaces for teeth. This means that cams also can be made

easily using micromachining processes. However, cams are not yet used in MEMS in the

traditional way but alternate manifestations of cams do exist. These are discussed in Sec.

15.6.