Page 544 - Cam Design Handbook

P. 544

THB16 9/19/03 8:04 PM Page 532

532 CAM DESIGN HANDBOOK

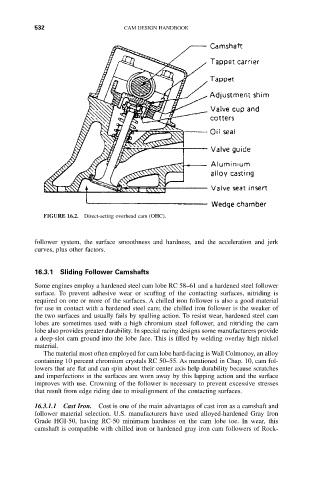

FIGURE 16.2. Direct-acting overhead cam (OHC).

follower system, the surface smoothness and hardness, and the acceleration and jerk

curves, plus other factors.

16.3.1 Sliding Follower Camshafts

Some engines employ a hardened steel cam lobe RC 58–61 and a hardened steel follower

surface. To prevent adhesive wear or scuffing of the contacting surfaces, nitriding is

required on one or more of the surfaces. A chilled iron follower is also a good material

for use in contact with a hardened steel cam; the chilled iron follower is the weaker of

the two surfaces and usually fails by spalling action. To resist wear, hardened steel cam

lobes are sometimes used with a high chromium steel follower, and nitriding the cam

lobe also provides greater durability. In special racing designs some manufacturers provide

a deep-slot cam ground into the lobe face. This is filled by welding overlay high nickel

material.

The material most often employed for cam lobe hard-facing is Wall Colmonoy, an alloy

containing 10 percent chromium crystals RC 50–55. As mentioned in Chap. 10, cam fol-

lowers that are flat and can spin about their center axis help durability because scratches

and imperfections in the surfaces are worn away by this lapping action and the surface

improves with use. Crowning of the follower is necessary to prevent excessive stresses

that result from edge riding due to misalignment of the contacting surfaces.

16.3.1.1 Cast Iron. Cost is one of the main advantages of cast iron as a camshaft and

follower material selection. U.S. manufacturers have used alloyed-hardened Gray Iron

Grade HGI-50, having RC-50 minimum hardness on the cam lobe toe. In wear, this

camshaft is compatible with chilled iron or hardened gray iron cam followers of Rock-