Page 546 - Cam Design Handbook

P. 546

THB16 9/19/03 8:04 PM Page 534

534 CAM DESIGN HANDBOOK

Cam

Lash compensator

hydraulic lifter

Valve

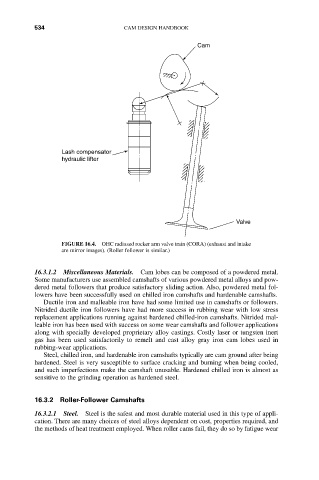

FIGURE 16.4. OHC radiused rocker arm valve train (CORA) (exhaust and intake

are mirror images). (Roller follower is similar.)

16.3.1.2 Miscellaneous Materials. Cam lobes can be composed of a powdered metal.

Some manufacturers use assembled camshafts of various powdered metal alloys and pow-

dered metal followers that produce satisfactory sliding action. Also, powdered metal fol-

lowers have been successfully used on chilled iron camshafts and hardenable camshafts.

Ductile iron and malleable iron have had some limited use in camshafts or followers.

Nitrided ductile iron followers have had more success in rubbing wear with low stress

replacement applications running against hardened chilled-iron camshafts. Nitrided mal-

leable iron has been used with success on some wear camshafts and follower applications

along with specially developed proprietary alloy castings. Costly laser or tungsten inert

gas has been used satisfactorily to remelt and cast alloy gray iron cam lobes used in

rubbing-wear applications.

Steel, chilled iron, and hardenable iron camshafts typically are cam ground after being

hardened. Steel is very susceptible to surface cracking and burning when being cooled,

and such imperfections make the camshaft unusable. Hardened chilled iron is almost as

sensitive to the grinding operation as hardened steel.

16.3.2 Roller-Follower Camshafts

16.3.2.1 Steel. Steel is the safest and most durable material used in this type of appli-

cation. There are many choices of steel alloys dependent on cost, properties required, and

the methods of heat treatment employed. When roller cams fail, they do so by fatigue wear