Page 545 - Cam Design Handbook

P. 545

THB16 9/19/03 8:04 PM Page 533

AUTOMOTIVE CAMSHAFT DYNAMICS 533

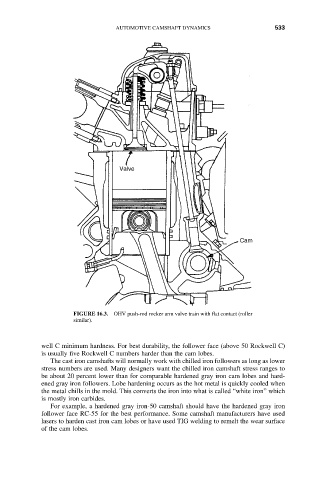

FIGURE 16.3. OHV push-rod rocker arm valve train with flat contact (roller

similar).

well C minimum hardness. For best durability, the follower face (above 50 Rockwell C)

is usually five Rockwell C numbers harder than the cam lobes.

The cast iron camshafts will normally work with chilled iron followers as long as lower

stress numbers are used. Many designers want the chilled iron camshaft stress ranges to

be about 20 percent lower than for comparable hardened gray iron cam lobes and hard-

ened gray iron followers. Lobe hardening occurs as the hot metal is quickly cooled when

the metal chills in the mold. This converts the iron into what is called “white iron” which

is mostly iron carbides.

For example, a hardened gray iron-50 camshaft should have the hardened gray iron

follower face RC-55 for the best performance. Some camshaft manufacturers have used

lasers to harden cast iron cam lobes or have used TIG welding to remelt the wear surface

of the cam lobes.