Page 195 - Carbon Nanotube Fibres and Yarns

P. 195

Mechanics modeling of carbon nanotube yarns 185

area in a CNT yarn is different in nature from the fiber-fiber interface in a

staple fiber yarn. Van der Waals (vdW) force plays a very important role in

tube-tube interface in a CNT yarn. The strong vdW interaction causes CNTs

to form bundles, which persist into the final yarn. The assembly structures of

the coagulation-based and aerogel-based CNT yarns differs from that of the

forest-spun yarn, which further complicates the establishment of a common

theory applicable to all types of CNT yarns. Despite all these differences, the

generic equations and models of conventional staple yarns can provide some

useful insights to the study of CNT yarns.

8.2.1 Continuum model of twisted yarn

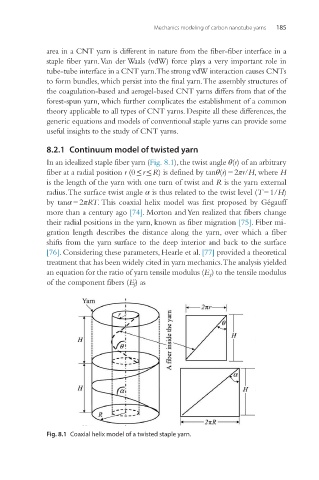

In an idealized staple fiber yarn (Fig. 8.1), the twist angle θ(r) of an arbitrary

fiber at a radial position r (0 ≤ r ≤ R) is defined by tanθ(r) = 2πr/H, where H

is the length of the yarn with one turn of twist and R is the yarn external

radius. The surface twist angle α is thus related to the twist level (T = 1/H)

by tanα = 2πRT. This coaxial helix model was first proposed by Gégauff

more than a century ago [74]. Morton and Yen realized that fibers change

their radial positions in the yarn, known as fiber migration [75]. Fiber mi-

gration length describes the distance along the yarn, over which a fiber

shifts from the yarn surface to the deep interior and back to the surface

[76]. Considering these parameters, Hearle et al. [77] provided a theoretical

treatment that has been widely cited in yarn mechanics. The analysis yielded

an equation for the ratio of yarn tensile modulus (E y ) to the tensile modulus

of the component fibers (E f ) as

Fig. 8.1 Coaxial helix model of a twisted staple yarn.