Page 49 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 49

12 Carraher’s Polymer Chemistry

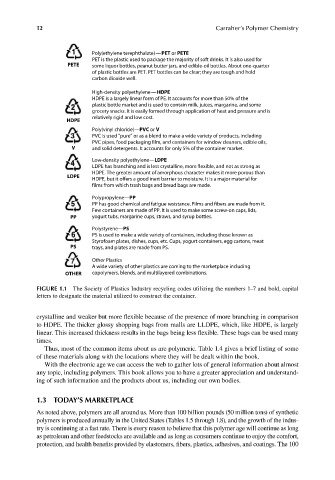

Poly(ethylene terephthalate) — PET or PETE

PET is the plastic used to package the majority of soft drinks. It is also used for

PETE some liquor bottles, peanut butter jars, and edible-oil bottles. About one-quarter

of plastic bottles are PET. PET bottles can be clear; they are tough and hold

carbon dioxide well.

High-density polyethylene — HDPE

HDPE is a largely linear form of PE. It accounts for more than 50% of the

plastic bottle market and is used to contain milk, juices, margarine, and some

grocery snacks. It is easily formed through application of heat and pressure and is

relatively rigid and low cost.

HDPE

Poly(vinyl chloride)—PVC or V

PVC is used “pure” or as a blend to make a wide variety of products, including

PVC pipes, food packaging film, and containers for window cleaners, edible oils,

V and solid detergents. It accounts for only 5% of the container market.

Low-density polyethylene—LDPE

LDPE has branching and is less crystalline, more flexible, and not as strong as

HDPE. The greater amount of amorphous character makes it more porous than

LDPE

HDPE, but it offers a good inert barrier to moisture. It is a major material for

films from which trash bags and bread bags are made.

Polypropylene—PP

PP has good chemical and fatigue resistance. Films and fibers are made from it.

Few containers are made of PP. It is used to make some screw-on caps, lids,

PP yogurt tubs, margarine cups, straws, and syrup bottles.

Polystyrene—PS

PS is used to make a wide variety of containers, including those known as

Styrofoam plates, dishes, cups, etc. Cups, yogurt containers, egg cartons, meat

PS trays, and plates are made from PS.

Other Plastics

A wide variety of other plastics are coming to the marketplace including

OTHER copolymers, blends, and multilayered combinations.

FIGURE 1.1 The Society of Plastics Industry recycling codes utilizing the numbers 1–7 and bold, capital

letters to designate the material utilized to construct the container.

crystalline and weaker but more flexible because of the presence of more branching in comparison

to HDPE. The thicker glossy shopping bags from malls are LLDPE, which, like HDPE, is largely

linear. This increased thickness results in the bags being less flexible. These bags can be used many

times.

Thus, most of the common items about us are polymeric. Table 1.4 gives a brief listing of some

of these materials along with the locations where they will be dealt within the book.

With the electronic age we can access the web to gather lots of general information about almost

any topic, including polymers. This book allows you to have a greater appreciation and understand-

ing of such information and the products about us, including our own bodies.

1.3 TODAY’S MARKETPLACE

As noted above, polymers are all around us. More than 100 billion pounds (50 million tons) of synthetic

polymers is produced annually in the United States (Tables 1.5 through 1.8), and the growth of the indus-

try is continuing at a fast rate. There is every reason to believe that this polymer age will continue as long

as petroleum and other feedstocks are available and as long as consumers continue to enjoy the comfort,

protection, and health benefits provided by elastomers, fibers, plastics, adhesives, and coatings. The 100

9/14/2010 3:35:52 PM

K10478.indb 12 9/14/2010 3:35:52 PM

K10478.indb 12