Page 532 - Carrahers_Polymer_Chemistry,_Eighth_Edition

P. 532

Rheology and Physical Tests 495

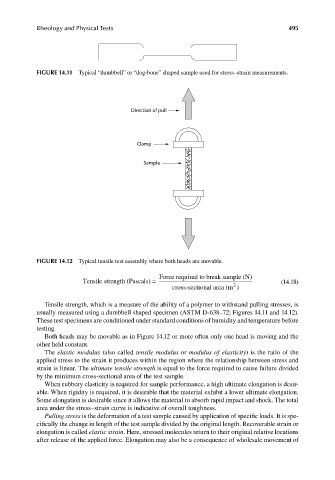

FIGURE 14.11 Typical “dumbbell” or “dog-bone” shaped sample used for stress–strain measurements.

Direction of pull

Clamp

Sample

FIGURE 14.12 Typical tensile test assembly where both heads are movable.

Force required to break sample (N)

Tensile strength (Pascals) = 2 (14.18)

cross-sectional area (m )

Tensile strength, which is a measure of the ability of a polymer to withstand pulling stresses, is

usually measured using a dumbbell shaped specimen (ASTM D-638–72; Figures 14.11 and 14.12).

These test specimens are conditioned under standard conditions of humidity and temperature before

testing.

Both heads may be movable as in Figure 14.12 or more often only one head is moving and the

other held constant.

The elastic modulus (also called tensile modulus or modulus of elasticity) is the ratio of the

applied stress to the strain it produces within the region where the relationship between stress and

strain is linear. The ultimate tensile strength is equal to the force required to cause failure divided

by the minimum cross-sectional area of the test sample.

When rubbery elasticity is required for sample performance, a high ultimate elongation is desir-

able. When rigidity is required, it is desirable that the material exhibit a lower ultimate elongation.

Some elongation is desirable since it allows the material to absorb rapid impact and shock. The total

area under the stress–strain curve is indicative of overall toughness.

Pulling stress is the deformation of a test sample caused by application of specific loads. It is spe-

cifically the change in length of the test sample divided by the original length. Recoverable strain or

elongation is called elastic strain. Here, stressed molecules return to their original relative locations

after release of the applied force. Elongation may also be a consequence of wholesale movement of

9/14/2010 3:42:38 PM

K10478.indb 495

K10478.indb 495 9/14/2010 3:42:38 PM