Page 87 - Catalysts for Fine Chemical Synthesis Vol 1 - Robert & Poignant

P. 87

epoxidation of allylic alcohols 73

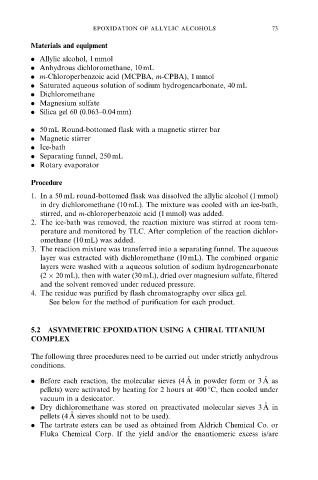

Materials and equipment

. Allylic alcohol, 1 mmol

. Anhydrous dichloromethane, 10 mL

. m-Chloroperbenzoic acid (MCPBA, m-CPBA), 1 mmol

. Saturated aqueous solution of sodium hydrogencarbonate, 40 mL

. Dichloromethane

. Magnesium sulfate

. Silica gel 60 (0.063±0.04 mm)

. 50 mL Round-bottomed flask with a magnetic stirrer bar

. Magnetic stirrer

. Ice-bath

. Separating funnel, 250 mL

. Rotary evaporator

Procedure

1. In a 50 mL round-bottomed flask was dissolved the allylic alcohol (1 mmol)

in dry dichloromethane (10 mL). The mixture was cooled with an ice-bath,

stirred, and m-chloroperbenzoic acid (1 mmol) was added.

2. The ice-bath was removed, the reaction mixture was stirred at room tem-

perature and monitored by TLC. After completion of the reaction dichlor-

omethane (10 mL) was added.

3. The reaction mixture was transferred into a separating funnel. The aqueous

layer was extracted with dichloromethane (10 mL). The combined organic

layers were washed with a aqueous solution of sodium hydrogencarbonate

(2 20 mL), then with water (30 mL), dried over magnesium sulfate, filtered

and the solvent removed under reduced pressure.

4. The residue was purified by flash chromatography over silica gel.

See below for the method of purification for each product.

5.2 ASYMMETRIC EPOXIDATION USING A CHIRAL TITANIUM

COMPLEX

The following three procedures need to be carried out under strictly anhydrous

conditions.

Ê

Ê

. Before each reaction, the molecular sieves (4 A in powder form or 3 A as

pellets) were activated by heating for 2 hours at 400 8C, then cooled under

vacuum in a desiccator.

Ê

. Dry dichloromethane was stored on preactivated molecular sieves 3 A in

Ê

pellets (4 A sieves should not to be used).

. The tartrate esters can be used as obtained from Aldrich Chemical Co. or

Fluka Chemical Corp. If the yield and/or the enantiomeric excess is/are