Page 93 - Catalysts for Fine Chemical Synthesis Vol 1 - Robert & Poignant

P. 93

epoxidation of allylic alcohols 79

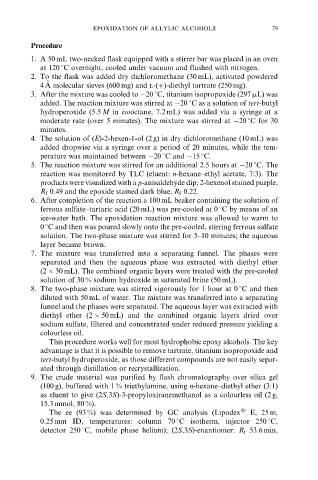

Procedure

1. A 50 mL two-necked flask equipped with a stirrer bar was placed in an oven

at 120 8C overnight, cooled under vacuum and flushed with nitrogen.

2. To the flask was added dry dichloromethane (30 mL), activated powdered

Ê

4 A molecular sieves (600 mg) and l-()-diethyl tartrate (250 mg).

3. After the mixture was cooled to ÿ20 8C, titanium isopropoxide (297 mL) was

added. The reaction mixture was stirred at ÿ20 8C as a solution of tert-butyl

hydroperoxide (5.5 M in isooctane, 7.2 mL) was added via a syringe at a

moderate rate (over 5 minutes). The mixture was stirred at ÿ20 8C for 30

minutes.

4. The solution of (E)-2-hexen-1-ol (2 g) in dry dichloromethane (10 mL) was

added dropwise via a syringe over a period of 20 minutes, while the tem-

perature was maintained between ÿ20 8C and ÿ15 8C.

5. The reaction mixture was stirred for an additional 2.5 hours at ÿ20 8C. The

reaction was monitored by TLC (eluent: n-hexane±ethyl acetate, 7:3). The

products were visualized with a p-anisaldehyde dip; 2-hexenol stained purple,

R f 0.49 and the epoxide stained dark blue, R f 0.22.

6. After completion of the reaction a 100 mL beaker containing the solution of

ferrous sulfate±tartaric acid (20 mL) was pre-cooled at 0 8C by means of an

ice-water bath. The epoxidation reaction mixture was allowed to warm to

0 8C and then was poured slowly onto the pre-cooled, stirring ferrous sulfate

solution. The two-phase mixture was stirred for 5±10 minutes; the aqueous

layer became brown.

7. The mixture was transferred into a separating funnel. The phases were

separated and then the aqueous phase was extracted with diethyl ether

(2 30 mL). The combined organic layers were treated with the pre-cooled

solution of 30 % sodium hydroxide in saturated brine (50 mL).

8. The two-phase mixture was stirred vigorously for 1 hour at 0 8C and then

diluted with 50 mL of water. The mixture was transferred into a separating

funnel and the phases were separated. The aqueous layer was extracted with

diethyl ether (2 50 mL) and the combined organic layers dried over

sodium sulfate, filtered and concentrated under reduced pressure yielding a

colourless oil.

This procedure works well for most hydrophobic epoxy alcohols. The key

advantage is that it is possible to remove tartrate, titanium isopropoxide and

tert-butyl hydroperoxide, as those different compounds are not easily separ-

ated through distillation or recrystallization.

9. The crude material was purified by flash chromatography over silica gel

(100 g), buffered with 1 % triethylamine, using n-hexane±diethyl ether (3:1)

as eluent to give (2S,3S)-3-propyloxiranemethanol as a colourless oil (2 g,

15.3 mmol, 80 %).

The ee (93 %) was determined by GC analysis (Lipodex 1 E, 25 m,

0.25 mm ID, temperatures: column 70 8C isotherm, injector 250 8C,

detector 250 8C, mobile phase helium); (2S,3S)-enantiomer: R t 53.6 min,