Page 95 - Catalysts for Fine Chemical Synthesis Vol 1 - Robert & Poignant

P. 95

epoxidation of allylic alcohols 81

5.2.4 CONCLUSION

This method, specific for the epoxidation of allylic alcohols, gives good results

if the reaction is carried out under strictly anhydrous conditions, otherwise

the yield or the enantiomeric excess can decrease, sometimes dramatically.This

can explain the small differences between the results obtained during the

validation experiments and the published results. All the different reagents

are commercially available; they can be used as received but in case of low

yield and/or enantiomeric excess they should be distilled and dried under an

inert atmosphere. Table 5.1 gives some other examples of substrates which

can be epoxidized using the procedure described above.

5.3 ASYMMETRIC EPOXIDATION OF (E)-UNDEC-2-EN-1-OL USING

POLY(OCTAMETHYLENE TARTRATE)

D.C. Sherrington, J.K. Karjalainen and O.E.O. Hormi

Department of Pure and Applied Chemistry, Thomas Graham Building, University of

Strathclyde, 295 Cathedral Street, Glasgow G1 1XL, Scotland, Tel: 44(0)1415482799,

m.p.a.smith@strath.ac.uk

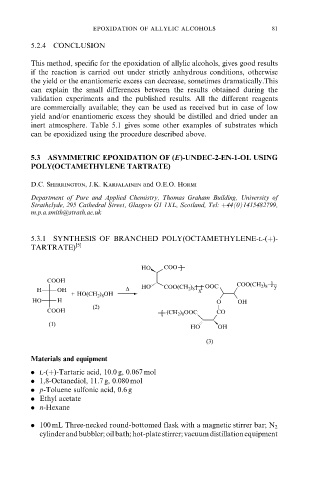

5.3.1 SYNTHESIS OF BRANCHED POLY(OCTAMETHYLENE-l-()-

TARTRATE) [5]

HO COO

COOH

H OH ∆ HO COO(CH 2 ) 8 x OOC COO(CH 2 ) 8 y

+ HO(CH 2 ) 8 OH

HO H O OH

(2)

COOH (CH 2 ) 8 OOC CO

(1)

HO OH

(3)

Materials and equipment

. l-()-Tartaric acid, 10.0 g, 0.067 mol

. 1,8-Octanediol, 11.7 g, 0.080 mol

. p-Toluene sulfonic acid, 0.6 g

. Ethyl acetate

. n-Hexane

. 100 mL Three-necked round-bottomed flask with a magnetic stirrer bar; N 2

cylinderandbubbler; oilbath;hot-platestirrer;vacuumdistillationequipment