Page 192 - Chalcogenide Glasses for Infrared Optics

P. 192

168 Cha pte r Se v e n

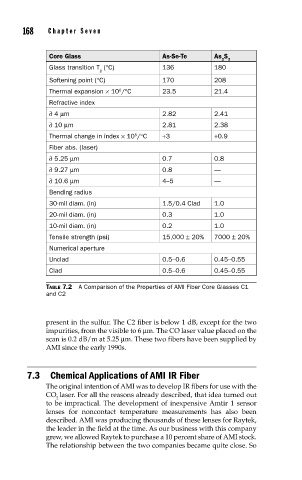

Core Glass As-Se-Te As S

2 3

Glass transition T (°C) 136 180

g

Softening point (°C) 170 208

6

Thermal expansion × 10 /°C 23.5 21.4

Refractive index

∂ 4 µm 2.82 2.41

∂ 10 µm 2.81 2.38

Thermal change in index × 10 /°C +3 +0.9

5

Fiber abs. (laser)

∂ 5.25 µm 0.7 0.8

∂ 9.27 µm 0.8 —

∂ 10.6 µm 4–5 —

Bending radius

30-mil diam. (in) 1.5/0.4 Clad 1.0

20-mil diam. (in) 0.3 1.0

10-mil diam. (in) 0.2 1.0

Tensile strength (psi) 15,000 ± 20% 7000 ± 20%

Numerical aperture

Unclad 0.5–0.6 0.45–0.55

Clad 0.5–0.6 0.45–0.55

TABLE 7.2 A Comparison of the Properties of AMI Fiber Core Glasses C1

and C2

present in the sulfur. The C2 fiber is below 1 dB, except for the two

impurities, from the visible to 6 µm. The CO laser value placed on the

scan is 0.2 dB/m at 5.25 µm. These two fibers have been supplied by

AMI since the early 1990s.

7.3 Chemical Applications of AMI IR Fiber

The original intention of AMI was to develop IR fibers for use with the

CO laser. For all the reasons already described, that idea turned out

2

to be impractical. The development of inexpensive Amtir 1 sensor

lenses for noncontact temperature measurements has also been

described. AMI was producing thousands of these lenses for Raytek,

the leader in the field at the time. As our business with this company

grew, we allowed Raytek to purchase a 10 percent share of AMI stock.

The relationship between the two companies became quite close. So