Page 219 - Chalcogenide Glasses for Infrared Optics

P. 219

IR Imaging Bundles Made fr om Chalcogenide Glass Fibers 195

5000 4500 4000 3500 3000 2500 2000 1500 cm –4

100.00

%T

2.4408; 90.29%T 2.9030; 80.96%T 5.2551; 86.25%T

80 1.0 dB/m

% Transmission 60 H 2 O 0.9 dB/m H 2 S 4.6 dB/m 3 dB/m

40

4.0289; 34.54%T 10 dB/m

20 5 dB/m

0.00

2.000 2.500 3.000 3.500 4.000 4.500 5.000 5.500 6.000 6.500 7.000

Wavelength (µm)

98/08/31 08:53

X: 10 scans, 4.0 cm –1

1.5 vs 5 m C–2 Fiber .039 Clad 98–87–1

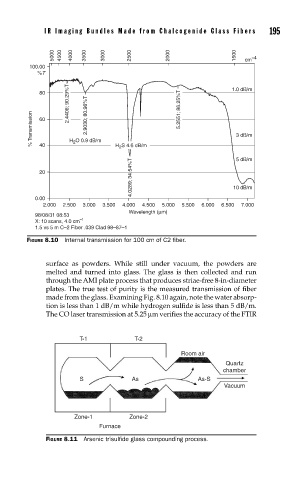

FIGURE 8.10 Internal transmission for 100 cm of C2 fi ber.

surface as powders. While still under vacuum, the powders are

melted and turned into glass. The glass is then collected and run

through the AMI plate process that produces striae-free 8-in-diameter

plates. The true test of purity is the measured transmission of fiber

made from the glass. Examining Fig. 8.10 again, note the water absorp-

tion is less than 1 dB/m while hydrogen sulfide is less than 5 dB/m.

The CO laser transmission at 5.25 µm verifies the accuracy of the FTIR

T-1 T-2

Room air

Quartz

chamber

S As As-S

Vacuum

Zone-1 Zone-2

Furnace

FIGURE 8.11 Arsenic trisulfi de glass compounding process.