Page 220 - Chalcogenide Glasses for Infrared Optics

P. 220

196 Cha pte r Ei g h t

results. The data presented here represent the present state of the art

at AMI and are reproducible using our 4- to 6-kg striae-free plates.

Our results have demonstrated that sustained drawing of small-

diameter fiber to form 70 count 10-m-long ribbons requires the use of

striae-free glass.

8.4.4 The 50 Percent Transmission Goal

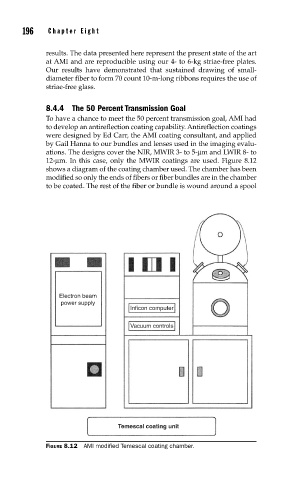

To have a chance to meet the 50 percent transmission goal, AMI had

to develop an antireflection coating capability. Antireflection coatings

were designed by Ed Carr, the AMI coating consultant, and applied

by Gail Hanna to our bundles and lenses used in the imaging evalu-

ations. The designs cover the NIR, MWIR 3- to 5-µm and LWIR 8- to

12-µm. In this case, only the MWIR coatings are used. Figure 8.12

shows a diagram of the coating chamber used. The chamber has been

modified so only the ends of fibers or fiber bundles are in the chamber

to be coated. The rest of the fiber or bundle is wound around a spool

Electron beam

power supply

Inficon computer

Vacuum controls

Temescal coating unit

FIGURE 8.12 AMI modifi ed Temescal coating chamber.