Page 225 - Chalcogenide Glasses for Infrared Optics

P. 225

IR Imaging Bundles Made fr om Chalcogenide Glass Fibers 201

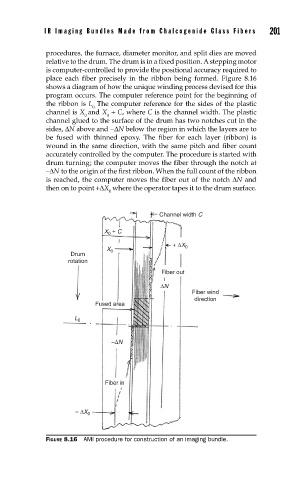

procedures, the furnace, diameter monitor, and split dies are moved

relative to the drum. The drum is in a fixed position. A stepping motor

is computer-controlled to provide the positional accuracy required to

place each fiber precisely in the ribbon being formed. Figure 8.16

shows a diagram of how the unique winding process devised for this

program occurs. The computer reference point for the beginning of

the ribbon is L The computer reference for the sides of the plastic

0.

channel is X and X + C, where C is the channel width. The plastic

0 0

channel glued to the surface of the drum has two notches cut in the

sides, ∆N above and −∆N below the region in which the layers are to

be fused with thinned epoxy. The fiber for each layer (ribbon) is

wound in the same direction, with the same pitch and fiber count

accurately controlled by the computer. The procedure is started with

drum turning; the computer moves the fiber through the notch at

–∆N to the origin of the first ribbon. When the full count of the ribbon

.

is reached, the computer moves the fiber out of the notch ∆N and

then on to point +∆X where the operator tapes it to the drum surface.

0

Channel width C

+ C

X 0

+ ∆X 0

X 0

Drum

rotation

Fiber out

∆N

Fiber wind

direction

Fused area

L 0

–∆N

Fiber in

– ∆X 0

FIGURE 8.16 AMI procedure for construction of an imaging bundle.