Page 224 - Chalcogenide Glasses for Infrared Optics

P. 224

200 Cha pte r Ei g h t

T T

Core E E

M M

Clad P P

Preset

counter

Drum

speed P Crucible pressurization

manifold

Traverse P

Layup traverse Core glass crucible & die

mechanism

Compumotor (computer

controlled) microstepper

Ovens Clad glass crucible & die

Laser diameter gauge

Split drum, diameter

releasing mechanism

Boston gear 10:1

reducer mounted

to a reliance

1.5-hp dc drive

motor with 60T

ring kit

Boston gear hd

pillow blocks, with

self-aligning sealed

bearings

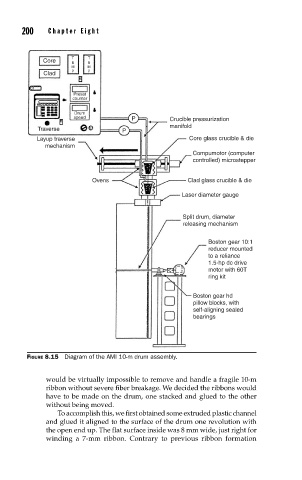

FIGURE 8.15 Diagram of the AMI 10-m drum assembly.

would be virtually impossible to remove and handle a fragile 10-m

ribbon without severe fiber breakage. We decided the ribbons would

have to be made on the drum, one stacked and glued to the other

without being moved.

To accomplish this, we first obtained some extruded plastic channel

and glued it aligned to the surface of the drum one revolution with

the open end up. The flat surface inside was 8 mm wide, just right for

winding a 7-mm ribbon. Contrary to previous ribbon formation