Page 228 - Chalcogenide Glasses for Infrared Optics

P. 228

204 Cha pte r Ei g h t

section where the ribbons could be formed and the layers could be

fused. At the end, the fused area would be cut in the middle to pro-

vide the coherent ends. The bodies of the fibers were wound on a thin

sheet of plastic stuck to the drum. When the winding was complete,

the edges of the plastic were folded over the loose fibers and sealed to

form a thin plastic sack the entire length of the bundle. After the fused

area was cut in the middle, the thin sack was placed in a shrinkable

plastic tube, heated to size, and sealed on each end to the metal con-

nectors. The bundle was wound from very high purity glass, all from

the same plate, homogeneous, striae-free, and low in water absorp-

tion (< 1 dB/m) and in hydrogen sulfide absorption (< 5 dB/m). The

quality of the glass led to a failure-free winding process with four

cores from the plate completing the bundle. The ribbon count was

66 unclad fibers, core diameter 108 µm, 47 layers for a total of 31,020 m.

The calculated active area was 71.2 percent, our record (absolute

maximum is 78.5 percent). The extra bundle was fabricated to employ

all we had learned to prepare a final improved version.

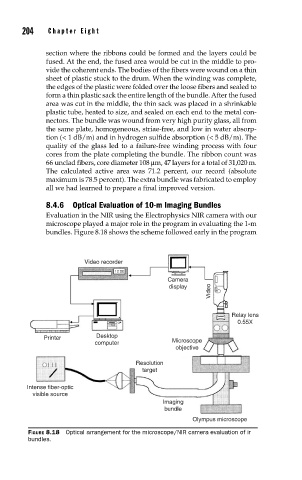

8.4.6 Optical Evaluation of 10-m Imaging Bundles

Evaluation in the NIR using the Electrophysics NIR camera with our

microscope played a major role in the program in evaluating the 1-m

bundles. Figure 8.18 shows the scheme followed early in the program

Video recorder

12:00

12:00

Camera

Video

display

Relay lens

0.55X

Printer Desktop

computer Microscope

objective

Resolution

target

Intense fiber-optic

visible source

Imaging

bundle

Olympus microscope

FIGURE 8.18 Optical arrangement for the microscope/NIR camera evaluation of ir

bundles.