Page 243 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 243

CATHODIC AND ANODIC PROTECTION 221

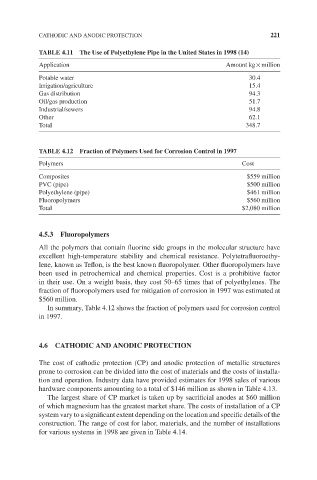

TABLE 4.11 The Use of Polyethylene Pipe in the United States in 1998 (14)

Application Amount kg × million

Potable water 30.4

Irrigation/agriculture 15.4

Gas distribution 94.3

Oil/gas production 51.7

Industrial/sewers 94.8

Other 62.1

Total 348.7

TABLE 4.12 Fraction of Polymers Used for Corrosion Control in 1997

Polymers Cost

Composites $559 million

PVC (pipe) $500 million

Polyethylene (pipe) $461 million

Fluoropolymers $560 million

Total $2,080 million

4.5.3 Fluoropolymers

All the polymers that contain fluorine side groups in the molecular structure have

excellent high-temperature stability and chemical resistance. Polytetrafluoroethy-

lene, known as Teflon, is the best known fluoropolymer. Other fluoropolymers have

been used in petrochemical and chemical properties. Cost is a prohibitive factor

in their use. On a weight basis, they cost 50–65 times that of polyethylenes. The

fraction of fluoropolymers used for mitigation of corrosion in 1997 was estimated at

$560 million.

In summary, Table 4.12 shows the fraction of polymers used for corrosion control

in 1997.

4.6 CATHODIC AND ANODIC PROTECTION

The cost of cathodic protection (CP) and anodic protection of metallic structures

prone to corrosion can be divided into the cost of materials and the costs of installa-

tion and operation. Industry data have provided estimates for 1998 sales of various

hardware components amounting to a total of $146 million as shown in Table 4.13.

The largest share of CP market is taken up by sacrificial anodes at $60 million

of which magnesium has the greatest market share. The costs of installation of a CP

system vary to a significant extent depending on the location and specific details of the

construction. The range of cost for labor, materials, and the number of installations

for various systems in 1998 are given in Table 4.14.