Page 318 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 318

296 CORROSION CONTROL AND PREVENTION

TABLE 4.46 Corrosion Failure Mode with Average Frequency of Occurrence

Failure Mode Average Frequency (%)

Cracking 36

General corrosion 26

Localized corrosion 20

Temperature effects 7

Velocity effects 5

Voltage effects 3

Hydrogen effects 2

Biological 0

Total 99

TABLE 4.47 Stress Corrosion Cracking Failures of Different Alloys

Material Average Frequency (%)

Stainless steels 61.4

Steel 30.4

Copper alloys 4.3

Nickel alloys 2.8

Titanium 0.7

Tantalum 0.3

Total 99.9

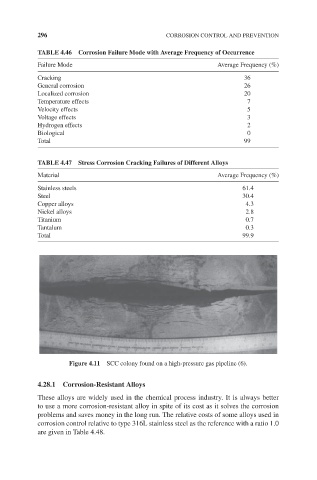

Figure 4.11 SCC colony found on a high-pressure gas pipeline (6).

4.28.1 Corrosion-Resistant Alloys

These alloys are widely used in the chemical process industry. It is always better

to use a more corrosion-resistant alloy in spite of its cost as it solves the corrosion

problems and saves money in the long run. The relative costs of some alloys used in

corrosion control relative to type 316L stainless steel as the reference with a ratio 1.0

are given in Table 4.48.