Page 380 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 380

358 CONSEQUENCES OF CORROSION

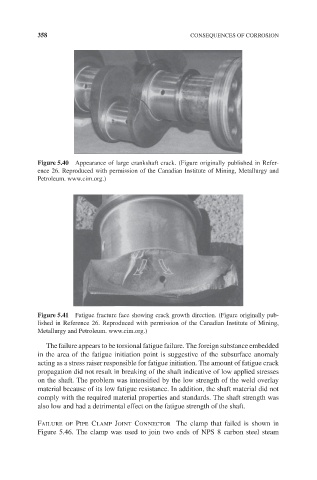

Figure 5.40 Appearance of large crankshaft crack. (Figure originally published in Refer-

ence 26. Reproduced with permission of the Canadian Institute of Mining, Metallurgy and

Petroleum. www.cim.org.)

Figure 5.41 Fatigue fracture face showing crack growth direction. (Figure originally pub-

lished in Reference 26. Reproduced with permission of the Canadian Institute of Mining,

Metallurgy and Petroleum. www.cim.org.)

The failure appears to be torsional fatigue failure. The foreign substance embedded

in the area of the fatigue initiation point is suggestive of the subsurface anomaly

acting as a stress raiser responsible for fatigue initiation. The amount of fatigue crack

propagation did not result in breaking of the shaft indicative of low applied stresses

on the shaft. The problem was intensified by the low strength of the weld overlay

material because of its low fatigue resistance. In addition, the shaft material did not

comply with the required material properties and standards. The shaft strength was

also low and had a detrimental effect on the fatigue strength of the shaft.

Failure of Pipe Clamp Joint Connector The clamp that failed is shown in

Figure 5.46. The clamp was used to join two ends of NPS 8 carbon steel steam