Page 392 - Challenges in Corrosion Costs Causes Consequences and Control(2015)

P. 392

370 CONSEQUENCES OF CORROSION

90 μm

Figure 5.65 Figure showing elongated grains (19).

To evaporator and

cooling water systems High–pressure still

Preheaters Condenser

Low–strength NH 3

Reboiler To cooling tower

Solutions from vent gas

Recovery scrubbers and

Steam

Aqua storage spheres Distillate storage

and reuse

Still bottoms

Cooling water

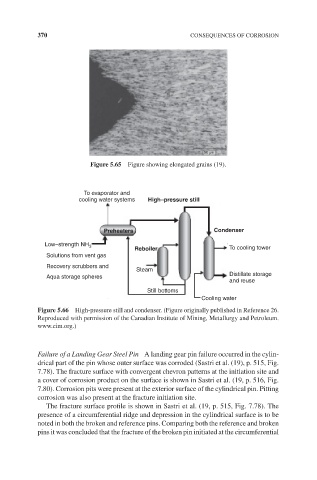

Figure 5.66 High-pressure still and condenser. (Figure originally published in Reference 26.

Reproduced with permission of the Canadian Institute of Mining, Metallurgy and Petroleum.

www.cim.org.)

Failure of a Landing Gear Steel Pin A landing gear pin failure occurred in the cylin-

drical part of the pin whose outer surface was corroded (Sastri et al. (19), p. 515, Fig.

7.78). The fracture surface with convergent chevron patterns at the initiation site and

a cover of corrosion product on the surface is shown in Sastri et al. (19, p. 516, Fig.

7.80). Corrosion pits were present at the exterior surface of the cylindrical pin. Pitting

corrosion was also present at the fracture initiation site.

The fracture surface profile is shown in Sastri et al. (19, p. 515, Fig. 7.78). The

presence of a circumferential ridge and depression in the cylindrical surface is to be

noted in both the broken and reference pins. Comparing both the reference and broken

pins it was concluded that the fracture of the broken pin initiated at the circumferential