Page 194 - Chemical Process Equipment - Selection and Design

P. 194

166 FLUID TRANSPORT EQUIPMENT

Dischargeofstage 0 1 2 3 4

EXAMPLE 7.13 Torr 0.3 2.1 15.1 107 760

Interstage Condensers "F 14 63.7 127.4

A four-stage ejector is to evacuate a system to 0.3Torr. The

compression ratio in each stage will be The bubblepoint temperature in the second stage is marginal with

normal cooling tower water, particularly with the practical

restriction to 5°F below the bubblepoint. At the discharge of the

(P4/PO)*" = (760/0.3)1'4 = 7.09. third stage, however, either a surface or barometric condenser is

quite feasible. At somewhat higher process pressure, two interstage

The individual stage pressures and corresponding water bubblepoint condensers may be practical with a four-stage ejector, as indicated

temperatures from the steam tables are on Figure 7.31.

Nozzle Fnq Diffuser When barometric condensers are used, the effluent water

temperature should be at least 5°F below the bubblepoint at the

prevailing pressure. A few bubblepoint temperatures at low

StppE: > pressures are:

P- 3

Absolute (in. Hg) 0.2 0.5 1.0 2.0

Bubblepoint "F 34.6 58.8 79.0 101.1

Interstage pressures can be estimated on the assumption that

compression ratios will be the same in each stage, with the suction

to the first stage at the system pressure and the discharge of the last

stage at atmospheric pressure. Example 7.13 examines at what

stages it is feasible to employ condensers so as to minimize steam

usage in subsequent stages.

EJECTOR THEORY

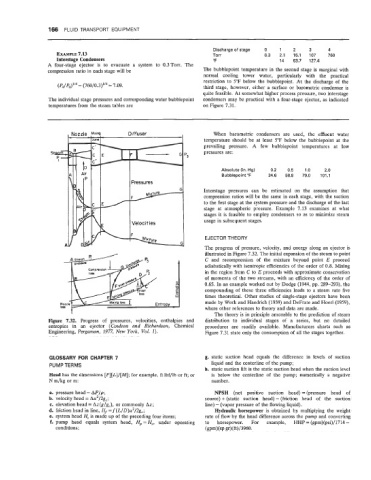

The progress of pressure, velocity, and energy along an ejector is

illustrated in Figure 7.32. The initial expansion of the steam to point

C and recompression of the mixture beyond point E proceed

adiabatically with isentropic efficiencies of the order of 0.8. Mixing

in the region from C to E proceeds with approximate conservation

of momenta of the two streams, with an efficiency of the order of

0.65. In an example worked out by Dodge (1944, pp. 289-293), the

compounding of these three efficiencies leads to a steam rate five

times theoretical. Other studies of single-stage ejectors have been

made by Work and Haedrich (1939) and DeFrate and Hoerl(1959),

where other references to theory and data are made.

The theory is in principle amenable to the prediction of steam

Figure 7.32. Progress of pressures, velocities, enthalpies and distribution to individual stages of a series, but no detailed

entropies in an ejector (Coulson and Richardson, Chemical procedures are readily available. Manufacturers charts such as

Engineering, Pergumon, 1977, New York, Vol. 1). Figure 7.31 state only the consumption of all the stages together.

GLOSSARY FOR CHAPTER 7 g. static suction head equals the difference in levels of suction

PUMP TERMS liquid and the centerline of the pump;

h. static suction lift is the static suction head when the suction level

Head has the dimensions [F][L]/[M]; for example, ft lbf/lb or ft; or is below the centerline of the pump; numerically a negative

N m/kg or m: number.

a. pressure head = AP/p; NPSH (net positive suction head) = (pressure head of

b. velocity head = Au2/2g,; source) + (static suction head) - (friction head of the suction

c. elevation head = Az(g/gc), or commonly Az; line) - (vapor pressure of the flowing liquid).

d. friction head in line, Hf = f (L/D)u2/2g,; Hydraulic horsepower is obtained by multiplying the weight

e. system head H, is made up of the preceding four items; rate of flow by the head difference across the pump and converting

f. pump head equals system head, H,=H,, under operating to horsepower. For example, HHP = (gpm)(psi)/l714 =

conditions; (gm) (sp gr) (ft) /3960.