Page 214 - Chemical Process Equipment - Selection and Design

P. 214

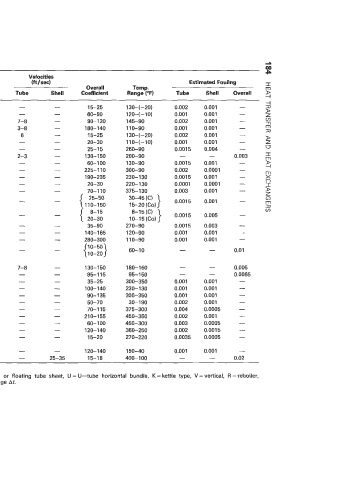

TABLE 8.4-(continued) a

Velocities

(WS4 Estimated Fouling I

Overall Temp.

In Tubes Outside Tubes Type Equipment Tube Shell Coefficient Range (OF) Tube Shell Overall

Lights and chloro-ethanes propylene refrig. KU 15-25 130-(-20) 0.002 0.001

Ethylene propylene refrig. KU 60-90 120-(-10) 0.001 0.001

Unsat. chloro HC water H 90-1 20 145-90 0.002 0.001

Unsat. chloro HC water H 180- 140 11 0-90 0.001 0.001

Unsat. chloro HC water H 15-25 1304-20) 0.002 0.001

Chloro-HC water KU 20-30 110-(-10) 0.001 0.001

Solvent and non cond. water H 25-15 260-90 0.001 5 0.004

Water propylene vapor H 130-150 200-90 - - 0.003 2

Water propylene H 60-1 00 130-90 0.0015 0.001 - 3

Water steam H 225-110 300-90 0.002 0.0001

Water steam H 190-235 230-130 0.001 5 0.001

Treated water steam (exhaust) H 20-30 220-130 0.0001 0.0001

Oil steam H 70-1 10 375- 1 30 0.003 0.001

Water propylene cooling and cond. H 0.0015 0.001

,

0 : " { 1 : 15-20 (CO)

{ 8-15 (C)

Chilled water air-chlorine (part and cond.) U 2::;: 10-15 (CO)} 0.0015 0.005

Water light HC, cool and cond. H 35-90 270-90 0.001 5 0.003

Water ammonia H 140-1 65 120-90 0.001 0.001

Water ammonia U 280-300 11 0-90 0.001 0.001

{:E} - -

Air-water vapor freon KU 60-10 0.01

C. Reboiling

Solvent, Copper-NH, steam H 130-150 180-1 60 - - 0.005

C, unsat. steam H 95-115 95-1 50 - - 0.0065

Chloro. HC steam VT 35-25 300-350 0.001 0.001 -

Chloro. unsat. HC steam VT 100- 140 230-130 0.001 0.001

Chloro. ethane steam VT 90-1 35 300-350 0.001 0.001

Chloro. ethane steam U 50-70 30-190 0.002 0.001

Solvent (heavy) steam H 70-115 375-300 0.004 0.0005

Mono-di-ethanolamines steam VT 210-155 450-350 0.002 0.001

Organics, acid, water steam VT 60-1 00 450-300 0.003 0.0005

Amines and water steam VT 120-140 360-250 0.002 0.001 5

Steam naphtha frac. Annulus 15-20 270-220 0.0035 0.0005

Long. F.N.

Propylene c,, c2- KU 120-140 150-40 0.001 0.001 -

Propvlene-butadiene butadiene, unsat. H 25-35 15-18 400- 1 00 - - 0.02

aFouling resistances are included in the listed values of U.

Unless specified, all water is untreated, brackish, bay or sea. Notes: H = horizontal, fixed or floating tube sheet, U = U-tube horizontal bundle, K= kettle type, V =vertical, R = reboiler,

T =thermosiphon, v = variable, HC = hydrocarbon, (C) = cooling range At, (Co) = condensing range At.

(Ludwig, 1983).