Page 230 - Chemical Process Equipment - Selection and Design

P. 230

200 HEAT TRANSFER AND HEAT EXCHANGERS

some arbitrary decisions based on as much current practice as

WAR END

fl in Figure 8.13. The key elements are:

possible.

MUD NPLI

A logic diagram of a heat exchanger design procedure appears

<:--Tj>

FIXED TUBESHEET

ONE

PASS

-I . ..................... WELL LIKE "A" STATIONARY HEAD 1. Selection of a tentative set of design parameters, Box 3 of Figure

8.13(a).

2. Rating of the tentative design, Figure 8.13(b), which means

FIXED TUBESHEET

TWO PAS SHELL LIKE "0" STATIONARY HE4D evaluating the performance with the best correlations and

wim LONGITUDINAL BAFFLE

calculation methods that are feasible.

3. Modification of some design parameters, Figure 8.13(c), then

rerating the design to meet thermal and hydraulic specifications

FIXED TUBESHEET

I LlKE 'W STATIONARY HEAD and economic requirements.

SPLIT FLOW

A procedure for a tentative selection of exchanger will be

.

.

. . _.._ .-.

IUTSIDE PACKED FLOATING HEA described following. With the exercise of some judgement, it is

feasible to perform simpler exchanger ratings by hand, but the

DOUBLE SPLll FLOW

present state of the art utilizes computer rating, with in-house

programs, or those of HTRI or HTFS, or those of commercial

services. More than 50 detailed numerical by hand rating examples

are in the book of Kern (1950) and several comprehensive ones in

the book of Ganapathy (1982).

PULL THROUGH FLOATING HEAI

TENTATIVE DESIGN

KEinE TYPE REBOILEP I The stepwise procedure includes statements of some rules based on

common practice.

U-TUBE BUNDLE

c:r-7;,

1. Specify the flow rates, terminal temperatures and physical

1 properties.

EXTERNALLY SEALED

SPECIAL HIGH PRESIURL CLOSUIII CROSS FLOW PLOAIING TUBESHEEl 2. Calculate the LMTD and the temperature correction factor F

from Table 8.3 or Figure 8.5.

(a) 3. Choose the simplest combination of shell and tube passes or

number of shells in series that will have a value of F above 0.8 or

so. The basic shell is 1-2, one shell pass and two tube passes.

4. Make an estimate of the overall heat transfer coefficient from

Tables 8.4-8.7.

5. Choose a tube length, normally 8, 12, 16, or 20 ft. The 8 ft long

exchanger costs about 1.4 times as much as the 20 ft one per unit

of surface.

4

6. Standard exchanger tube diameters are 0.75 or lin. OD, with

pitches shown in Table 8.13.

7. Find a shell diameter from Table 8.13 corresponding to the

selections of tube diameter, length, pitch, and number of passes

made thus far for the required surface. As a guide, many heat

exchangers have length to shell diameter ratios between 6 and 8.

8. Select the kinds and number of baffles on the shell side.

The tentative exchanger design now is ready for detailed

evaluation with the best feasible heat transfer and pressure drop

data. The results of such a rating will suggest what changes may be

needed to satisfy the thermal, hydraulic, and economic require-

ments for the equipment. Example 8.10 goes through the main part

1. SHELL 8. FLOATING HEAD FWGE 16. TRANSVERSE BAFFLES OR of such a design.

2. SHELL COVER 9. CHANNEL PARTITION SUPPORT PLATES

3. SHELLCHWNEL 10. STATIONARY TUBESHEET 18. IMPINGEMENT BAFFLE

1. 5HELLCOVEfl END FLANGE 11. CHANNEL 17. VENT CONNECTION

6. SHELLNOZZLE 12. CHANNELCOVER 18. DRAIN CONNECTION 8.8. CONDENSERS

6, f LOATING TUBESHEET 13. CHANNEL NOZZLE 19. TEST CONNECTION

1. FLOATING HEAD 14. TIE ROD9 ANDSPACERS 20. SUPPORT SADDLES

21. LlFTlNGRlNG Condensation may be performed inside or outside tubes, in

horizontal or vertical positions. In addition to the statements made

in the previous section about the merits of tube side or shell side:

When freezing can occur, shell side is preferable because it is less

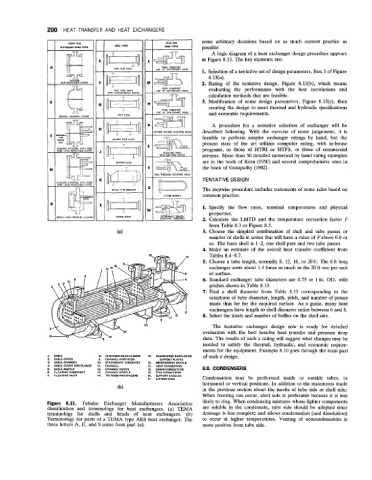

Figure 8.11. Tubular Exchanger Manufacturers Association likely to clog. When condensing mixtures whose lighter components

classification and terminology for heat exchangers. (a) TEMA are soluble in the condensate, tube side should be adopted since

terminology for shells and heads of heat exchangers. (b) drainage is less complete and allows condensation (and dissolution)

Terminology for parts of a TEMA type AES heat exchanger. The to occur at higher temperatures. Venting of noncondensables is

three letters A, E, and S come from part (a). more positive from tube side.