Page 226 - Chemical Process Equipment - Selection and Design

P. 226

196 HEAT TRANSFER AND HEAT EXCHANGERS

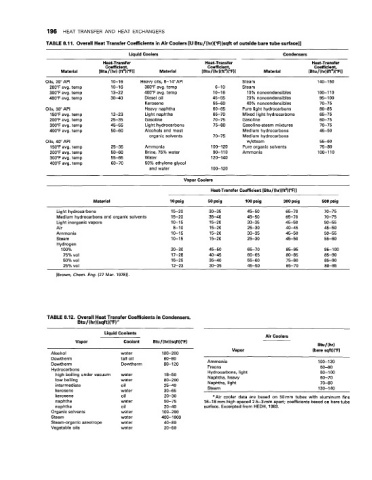

TABLE 8.11. Overall Heat Transfer Coefficients in Air Coolers [U Btu/(hr)("F)(sqft of outside bare tube surface)]

Liquid Coolers Condensers

Heat-Transfer Heat-Transfer Heat-Transfer

Coefficient, Coefficient, Coefficient,

Material [Btu/(hr) (ft?PFIl Material [Btu/(hr)(ft2)PF)I Material [Btu/(hr)(ft%WI

Oils, 20" API 10-16 Heavy oils, 8-14"API Steam 140-150

200°F avg. temp 10-1 6 300°F avg. temp 6-10 Steam

300°F avg. temp 13-22 400°F avg. temp 10-16 10% noncondensibles 1 00-1 1 0

400°F avg. temp 30-40 Diesel oil 45-55 20% noncondensibles 95-1 00

Kerosene 55-60 40% noncondensibles 70-75

Oils, 30" API Heavy naphtha 60-65 Pure light hydrocarbons 80-85

150°F avg. temp 12-23 Light naphtha 65-70 Mixed light hydrocarbons 65-75

200°F avg. temp 25-35 Gasoline 70-75 Gasoline 60-75

300°F avg. temp 45-55 Light hydrocarbons 75-80 Gasoline-steam mixtures 70-75

400°F avg. temp 50-60 Alcohols and most Medium hydrocarbons 45-50

organic solvents 70-75 Medium hydrocarbons

Oils, 40" API wlsteam 55-60

150°F avg. temp 25-35 Ammonia 100-120 Pure organic solvents 75-80

200°F avg. temp 50-60 Brine, 75% water 90-110 Ammonia 100-110

300°F avg. temp 55-65 Water 120-140

400°F avg. temp 60-70 50% ethylene glycol

and water 100-120

Vapor Coolers

Heat-Transfer Coefficient [Btu/(hr)(*)PF)l

Material 10 psig 50 psig 100 psig 300 psig 500 psig

~

Light hydrocarbons 15-20 30-35 45-50 65-70 70-75

Medium hydrocarbons and organic solvents 15-20 35-40 45-50 65-70 70-75

Light inorganic vapors 10-15 15-20 30-35 45-50 50-55

Air 8-10 15-20 25-30 40-45 45-50

Ammonia 10-15 15-20 30-35 45-50 50-55

Steam 10-15 15-20 25-30 45-50 55-60

Hydrogen

100% 20-30 45-50 65-70 85-95 95-100

75% VOI 17-28 40-45 60-65 80-85 85-90

50% vol 15-25 35-40 55-60 75-80 85-90

25% vol 12-23 30-35 45-50 65-70 80-85

~

[Brown, Chem. Eng. (27 Mar. 1978)l.

TABLE 8.12. Overall Heat Transfer Coefficients in Condensers,

Btu/(hr)(sqft)("F)a

Liquid Coolants

Air Coolers

Vapor Coolant Btu/(hr)(sqft)("F)

Btu/(hr)

Vapor (bare sqft)("F)

Alcohol water 100-200

Dowtherm tall oil 60-80

Dowtherm Dowtherm 80-1 20 Ammonia 100-120

Hydrocarbons Freons 60-80

Hydrocarbons, light

80-1 00

high boiling under vacuum water 18-50

low boiling water 80-200 Naphtha, heavy 60-70

intermediate oil 25-40 Naphtha, light 70-80

kerosene water 30-65 Steam 130-140

kerosene oil 20-30 "Air cooler data are based on 50mm tubes with aluminum fins

naphtha water 50-75 16-18 mm high spaced 2.5-3 mm apart; coefficients based on bare tube

naphtha oil 20-40 surface. Excerpted from HEDH, 1983.

Organic solvents water 100-200

Steam water 400-1 000

Steam-organic azeotrope water 40-80

Vegetable oils water 20-50