Page 225 - Chemical Process Equipment - Selection and Design

P. 225

8.7. SHELL-AND-TUBE HEAT EXCHANGERS 195

Forced draft arrangement, from below the tubes, Figure 8.4(h),

develops high turbulence and consequently high heat transfer

coefficients. Escape velocities, however, are low, 3 m/sec or so, and

as a result poor distribution, backmixing and sensitivity to cross

currents can occur. With induced draft from above the tubes, Figure

8.4(g), escape velocities may be of the order of 10 m/sec and better

flow distribution results. This kind of installation is more expensive,

the pressure drops are higher, and the equipment is bathed in hot

air which can be deteriorating. The less solid mounting also can

result in noisier operation.

Correlations for friction factors and heat transfer coefficients

are cited in HEDH. Some overall coefficients based on external

bare tube surfaces are in Tables 8.11 and 8.12. For single passes in

cross flow, temperature correction factors are represented by Figure

83c) for example; charts for multipass flow on the tube side are

given in HEDH and by Kays and London (1984), for example.

Preliminary estimates of air cooler surface requirements can be

made with the aid of Figures 8.9 and 8.10, which are applied in

Example 8.9.

DOUBLE-PIPES

This kind of exchanger consists of a central pipe supported within a

(i) Parallel and counter flows larger one by packing glands [Fig. 8.4(a)]. The straight length is

limited to a maximum of about 20 ft; otherwise the center pipe will

sag and cause poor distribution in the annulus. I: is customary to

operate with the high pressure, high temperature, high density, and

corrosive fluid in the inner pipe and the less demanding one in the

annulus. The inner surface can be provided with scrapers [Fig.

8.4(b)] as in dewaxing of oils or crystallization from solutions.

External longitudinal fins in the annular space can be used to

improve heat transfer with gases or viscous fluids. When greater

heat transfer surfaces are needed, several double-pipes can be

(i i 1 Countercurrent flows stacked in any combination of series or parallel.

Double-pipe exchangers have largely lost out to shell-and-tube

units in recent years, although Walker (1982) lists 70 manufacturers

of them. They may be worth considering in these situations:

1. When the shell-side coefficient is less than half that of the tube

side; the annular side coefficient can be made comparable to the

tube side.

2. Temperature crosses that require multishell shell-and-tube units

[iii) Parallel flows throughout

can be avoided by the inherent true countercurrent flow in

(b) double pipes.

3. High pressures can be accommodated more economically in the

annulus than they can in a larger diameter shell.

In nl 4. At duties requiring only 100-200 sqft of surface the double-pipe

may be more economical, even in comparison with off-the-shelf

units.

The process design of double-pipe exchangers is practically the

simplest heat exchanger problem. Pressure drop calculation is

straightforward. Heat transfer coefficients in annular spaces have

been investigated and equations are cited in Table 8.10. A chapter

is devoted to this equipment by Kern (1950).

8.7. §HELL-AND-TUBE HEAT EXCHANGERS

Such exchangers are made up of a number of tubes in parallel and

(Cii

series through which one fluid travels and enclosed in a shell

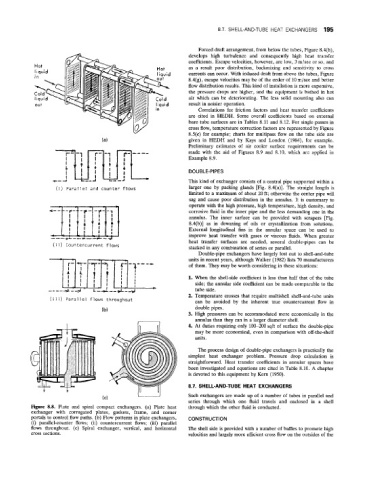

Figure 8.8. Plate and spiral compact exchangers. (a) Plate heat through which the other fluid is conducted.

exchanger with corrugated plates, gaskets, frame, and corner

portals to control flow paths. (b) Flow patterns in plate exchangers, CONSTRUCTION

(i) parallel-counter flows; (ii) countercurrent flows; (iii) parallel

flows throughout. (c) Spiral exchanger, vertical, and horizontal The shell side is provided with a number of baffles to promote high

cross sections. velocities and largely more efficient cross flow on the outsides of the