Page 318 - Chemical Process Equipment - Selection and Design

P. 318

282 DRYERS AND COOLING TOWERS

RETURN

E t.4 13

a. Atmospheric towers are effective when prevailing wind velocities

DECKS A 8 B DECKS C 8 D are 5 miles/hr or more. For access to the wind they are narrow

but long, lengths of 2000 ft having been constructed. Water drift

kl-l/B"J3/B"~ ?/8"

111111 losses are relatively large. The savings because of elimination of

tall chimney or fan power is counterbalanced by increased size

because of less efficient cross flow and variations in wind

velocity.

VERTICAL SPACING A:9",B: 12" VERTICAL SPACING C:16", D=24" b. Chimney assisted natural draft towers also eliminate fans. Most

of the structure is the chimney, the fill occupying only 10-12%

DECK E DECK F

of the tower height at the bottom. The temperature and

humidity of the air increase as the air flows upward so that its

buoyancy increases and results in rapid movement through the

chimney. Smaller units are made as circular cylinders since these

t can be built rapidly. The hyperboloidal shape has greater

--I 3-1/4" strength for a given wall thickness. In towers as large as

VERTICAL SPACING 24" VERTICAL SPACING 24" 250ftdia and 450ft high, wall thicknesses of 5-8in. of rein-

DECK H ,?/d'n ?/8" forced concrete are adequate. The enlarged cross section at

the top converts some kinetic energy into pressure energy which

assists in dispelling the exit humid air into the atmosphere.

The ratio of base diameter to height is 0.75-0.85, the ratio

of throat and base diameters is 0.55-0.65, and the ratio of

vertical depth of air opening to base diameter is 0.1-0.12. Air

VERTICAL SPACINQ 24" I VERTICAL SPAEING 24" velocity through the tower is 3-6 ft/sec, water flow rates range

from 600 to 1800 lb/(hr)(sqft). Two towers each 375 ft high are

able to service a 500 MW power plant. Natural draft towers are

uneconomical below heights of 70 ft. The upper limit is imposed

principally by environmental visual considerations; towers 500 ft

high are in existence. A cost comparison is made with item d.

c. Hyperbolic fan assisted towers can have as much as three times

the capacity of the same size natural draft towers. The fans

VERTICAL SPACING 24" VERTICAL SPACING 24" provide greater control than the natural draft systems; for

example, they may be turned on only at peak loads. Rules of

Factors in Eq. 9.38 for the Number of Decks thumb cited by Cheremisinoff and Cheremisinoff (1981) for

relative sizing is that fan assisted hyperbolic towers may have

Deck Type a b

diameters 2/3 and heights 1/2 those of purely natural draft designs.

A 0.060 0.62 d. Countercurrent-induced draft construction is the most widely

B 0.070 0.62 used type in process industries. Mechanical draft is capable of a

C 0.092 0.60 greater degree of control than natural draft and such towers are

D 0.119 0.58 able in some cases to cool the water within 2°F of the wet bulb

E 0.110 0.46

F 0.100 0.51 temperature of the air. The elevated fan location introduces

G 0.104 0.57 some structural and noise problems. The flow of air is quite

H 0.127 0.47 uniform across the cross section and its discharge is positive and

I 0.135 0.57 at high velocity so that there is little backflow of humid air into

J 0.103 0.54 the tower. A cost comparison (dated 1978) with hyperbolic

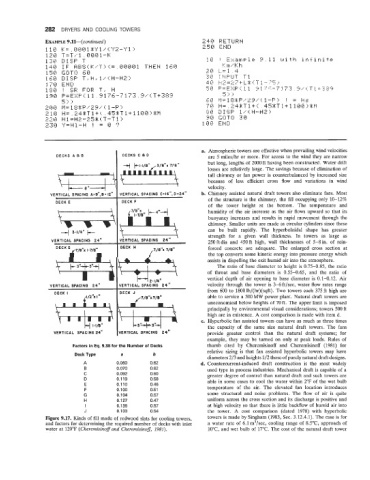

Figure 9.17. Kinds of fill made of redwood slats for cooling towers, towers is made by Singham (1983, Sec. 3.12.4.1). The case is for

and factors for determining the required number of decks with inlet a water rate of 6.1 m3/sec, cooling range of 8.5"C, approach of

water at 120°F (Cherernisinof and Cherernisinof, 1981). lWC, and wet bulb of 17°C. The cost of the natural draft tower