Page 316 - Chemical Process Equipment - Selection and Design

P. 316

280 DRYERS AND COOLING TOWERS

Equilibrium

c'

c-

c- c

h=f(T)

T, T,

b)

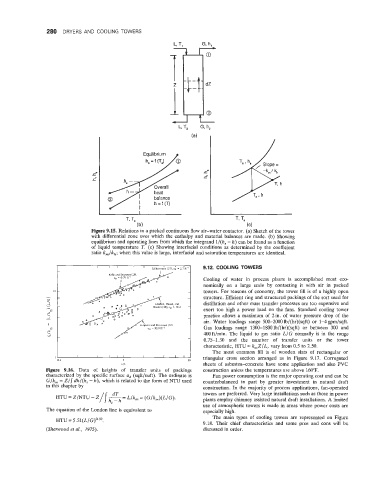

Figure 9.15. Relations in a packed continuous flow air-water contactor. (a) Sketch of the tower

with differential zone over which the enthalpy and material balances are made. (b) Showing

equilibrium and operating lines from which the integrand l/(hs - h) can be found as a function

of liquid temperature T. (c) Showing interfacial conditions as determined by the coefficient

ratio k,,,/k,; when this value is large, interfacial and saturation temperatures are identical.

9.12. COOLING TOWERS

Cooling of water in process plants is accomplished most eco-

nomically on a large scale by contacting it with air in packed

towers. For reasons of economy, the tower fill is of a highly open

structure. Efficient ring and structured packings of the sort used for

distillation and other mass transfer processes are too expensive and

exert too high a power load on the fans. Standard cooling tower

practice allows a maximum of 2in. of water pressure drop of the

air. Water loadings range 500-2000 lb/(hr)(sqft) or 1-4 gpm/sqft.

Gas loadings range 1300-1800 lb/(hr)(sqft) or between 300 and

400ft/min. The liquid to gas ratio L/G normally is in the range

0.75-1.50 and the number of transfer units or the tower

characteristic, HTU = k,,,Z/L, vary from 0.5 to 2.50.

The most common fill is of wooden slats of rectangular or

I I I I I I I I I 1 triangular cross section arranged as in Figure 9.17. Corrugated

0.1 I IO

G/L sheets of asbestos-concrete have some application and also PVC

Figure 9.16. Data of heights of transfer units of packings construction unless the temperatures are above 160°F.

characterized by the specific surface ad (sqft/cuft). The ordinate is Fan power consumption is the major operating cost and can be

G/k, = Z/l dh/(h, - h), which is related to the form of NTU used counterbalanced in part by greater investment in natural draft

in this chapter by construction. In the majority of process applications, fan-operated

towers are preferred. Very large installations such as those in power

plants employ chimney assisted natural draft installations. A limited

use of atmospheric towers is made in areas where power costs are

The equation of the London line is equivalent to especially high.

HTU = 5.51(L/G)0.s9. The main types of cooling towers are represented on Figure

9.18. Their chief characteristics and some pros and cons will be

(Sherwood et al., 1975). discussed in order.