Page 68 - Chemical Process Equipment - Selection and Design

P. 68

40 PROCESS CONTROL

Ill I

'F

!I

II

I

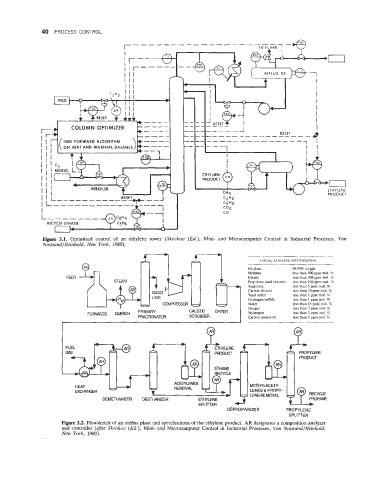

Figure 3.1. Optimized control of an ethylene tower (Skrokov (Ed.), Mini- and Microcomputer Control in Industrial Processes, Van

NostrandlReinhold, New York, 1980).

TYPICAL ETHYLENE SPECIFICATIONS

Ethylene 99.95% weight

Methane less than 500 ppm mol. %

FEED Ethane less than 500 ppm mol. %

Propylene (and heavier) less than 100 ppm mol. %

Acetylene less than 5 ppm mol. %

Carbon dioxide less than IO ppm mol. %

Total sulfur less than 5 ppm mol. '3%

Hydrogen sulfide less than I ppm mol. %

COMFRESCR Water less than 15 ppm mol. %

Oxygen less than 5 ppm mol. %

CAUSTIC DRYER Hydrogen less than I ppm mol. '3%

SCRUBBER Carbon monoxide less than 5 ppm mol. %

I

I

PROPYLENE

PF(OWCT

METHYIACETY-

LENES 8 PROPY-

LENE REMOVAL RECYCLE

DEMETHANEER DEETHANER ETHYLENE

SPLITTER

DEPROPANIZER PROPYLENE

SPLITTER

Figure 3.2. Flowsketch of an olefins plant and specifications of the ethylene product. AR designates a composition analyzer

and controller (after Skrokov (Ed.), Mini- and Microcomputer Control in Industrial Processes, Van NostrandlReinhoZd,

New York, 1980).