Page 72 - Chemical Process Equipment - Selection and Design

P. 72

44 PROCESS CONTROL

. I

(a) 1 SUMP

STEAM

1 SUMP

(C) i SUMP

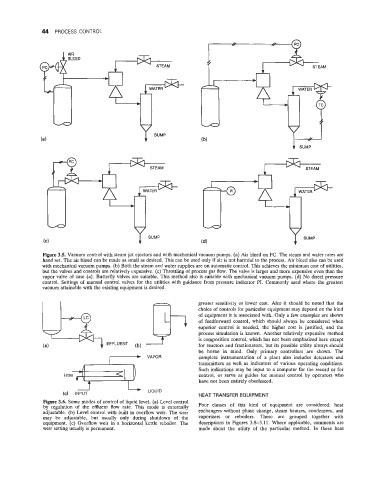

Figure 3.5. Vacuum control with steam jet ejectors and with mechanical vacuum pumps. (a) Air bleed on PC. The steam and water rates are

hand set. The air bleed can be made as small as desired. This can be used only if air is not harmful to the process. Air bleed also can be used

with mechanical vacuum pumps. (b) Both the steam and water supplies are on automatic control. This achieves the minimum cost of utilities,

but the valves and controls are relatively expensive. (c) Throttling of process gas flow. The valve is larger and more expensive even than the

vapor valve of case (a). Butterfly valves are suitable. This method also is suitable with mechanical vacuum pumps. (d) No direct pressure

control. Settings of manual control valves for the utilities with guidance from pressure indicator PI. Commonly used where the greatest

vacuum attainable with the existing equipment is desired.

greater sensitivity or lower cost. Also it should be noted that the

choice of controls for particular equipment may depend on the kind

of equipment it is associated with. Only a few examples are shown

of feedforward control, which should always be considered when

superior control is needed, the higher cost is justified, and the

process simulation is known. Another relatively expensive method

is composition control, which has not been emphasized here except

EFFLUENT for reactors and fractionators, but its possible utility always should

be borne in mind. Only primary controllers are shown. The

complete instrumentation of a plant also includes detectors and

transmitters as well as indicators of various operating conditions.

Such indications may be input to a computer for the record or for

control, or serve as guides for manual control by operators who

have not been entirely obsolesced.

I

(c) INPUT - LIQUID HEAT TRANSFER EQUIPMENT

Figure 3.6. Some modes of control of liquid level. (a) Level control

by regulation of the effluent flow rate. This mode is externally Four classes of this kind of equipment are considered: heat

adjustable. (b) Level control with built in overflow weir. The weir exchangers without phase change, steam heaters, condensers, and

may be adjustable, but usually only during shutdown of the vaporizers or reboilers. These are grouped together with

equipment. (c) Overflow weir in a horizontal kettle reboiler. The descriptions in Figures 3.8-3.11. Where applicable, comments are

weir setting usually is permanent. made about the utility of the particular method. In these heat